307-638ą11

MAINTENANCE

Daily Care and Cleaning

WARNING

To reduce the risk of serious bodily injury, including

splashing in the eyes or on the skin or electric

shock, always follow the Pressure Relief Proce-

dure Warning on page 9 when shutting off the sys-

tem, when you stop spraying and before checking,

servicing, installing, cleaning or changing any part

in the system.

CAUTION

Clean all parts with a non–conductive solvent,

compatible with the fluid being sprayed.

Conductive solvents can cause the gun to

malfunction.

Do not use any cleaning method which may al-

low solvent into the gun air passages. Solvent

left in the gun passages could result in a poor qual-

ity paint finish and may draw current and reduce

the electrostatic effect. Point the gun down while

cleaning to prevent dirty solvent from running back

into the air passages. NEVER IMMERSE THE

GUN IN SOLVENT.

1.

Clean the fluid and air line filters daily.

2.

Clean the outside of the gun daily with a soft cloth

dampened in a compatible solvent.

3.

Clean the air cap and fluid nozzle daily, minimum.

Some applications require more frequent cleaning.

Replace the fluid nozzle and air cap if they are dam-

aged. See Clean the Air Cap and Fluid Nozzle.

4.

Check the electrode wire. Straighten if bent, and re-

place if broken or damaged. See Electrode Needle

Replacement.

5.

Check all of the work hangers for build-up of material;

clean them, if necessary.

Clean the Air Cap and Fluid Nozzle

CAUTION

Do not use metal tools to clean the air cap holes as

this may scratch them, and make sure the elec-

trode wire is not damaged. Scratches in the air cap

holes or a damaged electrode wire can distort the

spray pattern.

Equipment needed:

Soft bristle brush (supplied).

Fluid nozzle wrench (supplied).

Solvent compatible with fluid being sprayed.

Procedure:

1.

Follow the Pressure Relief Procedure Warning on

page 9.

2.

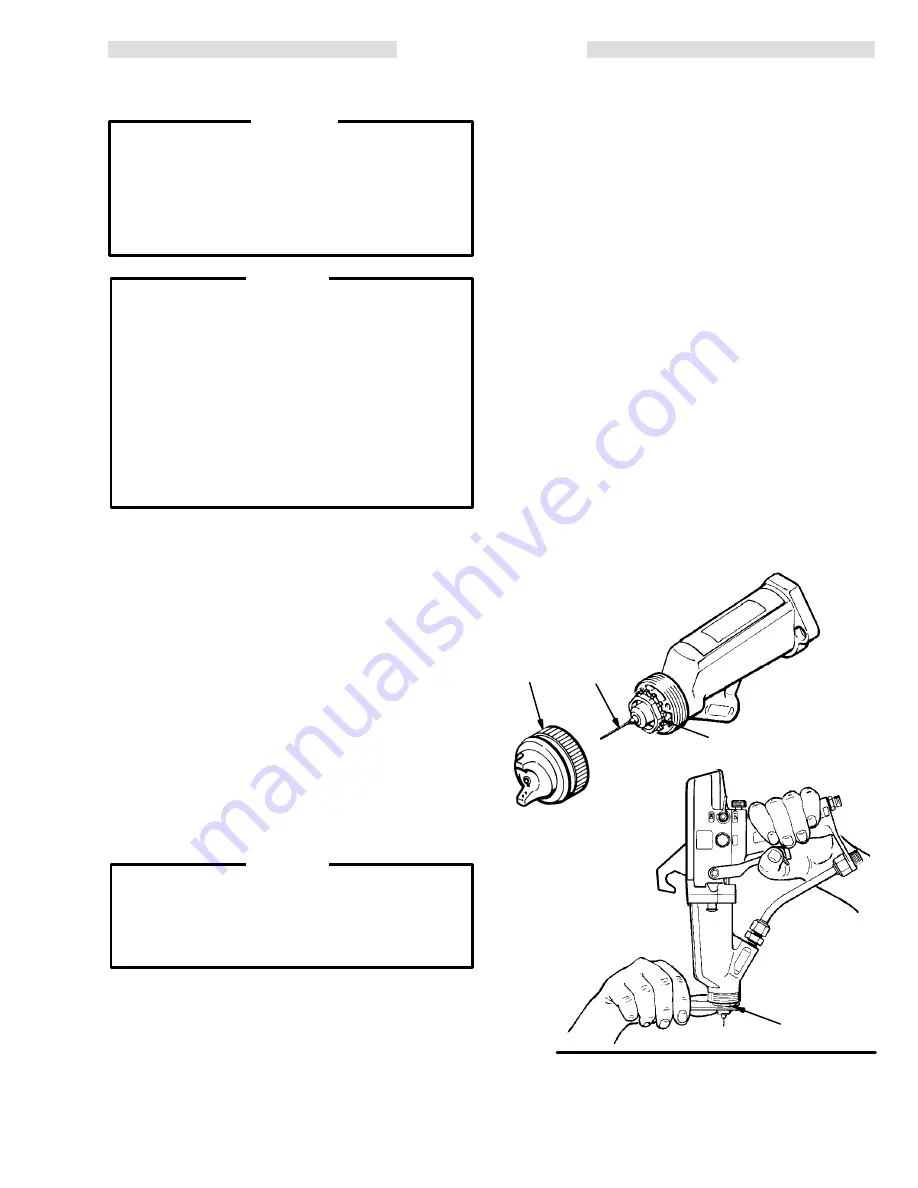

Remove the air cap assembly (14). See Fig 6.

3.

Turn the locking pin (84) to the unlocked position.

4.

Squeeze the gun trigger and remove the fluid nozzle

with the fluid nozzle wrench (59g) supplied. Make

sure the front of the gun is held down. See Fig 6.

5.

Use the soft bristle brush (59a) supplied and solvent

to clean the air cap, fluid nozzle, and front part of the

gun.

6.

Squeeze the gun trigger and screw the fluid nozzle

back into gun. Tighten the nozzle securely with the

wrench (59g) supplied. Torque the fluid nozzle to

1.1–1.4 N

m (10–12 in–lb). See Fig 6. Turn the lock-

ing pin to the locked position.

7.

Carefully reinstall the air cap assembly. Avoid bend-

ing the electrode (12). Tighten the retaining nut so it

is snug, allowing the air cap to turn with resistance. If

too tight, the spray pattern will be distorted.

Fig 6

KEY

12

Electrode

13

Fluid Nozzle

14

Air Cap Assembly

59g

Wrench

12

13

14

Torque to

1.1–1.4 N

m

(10–12 in–lb)

59g

Summary of Contents for 218-026

Page 2: ......