3

If secondary drain is not installed, the secondary access

must be plugged.

CAUTION

NOTE:

Trapped lines are required by many local codes. In the

absence of any prevailing local codes, please refer to the

requirements listed in the Uniform Mechanical Building Code.

A drain trap in a

draw-through

application prevents air from

being drawn back through the drain line during fan operation

thus preventing condensate from draining, and if connected to

a sewer line to prevent sewer gases from being drawn into the

airstream during blower operation. In a

blow-through

applica-

tion the drain trap prevents conditioned air from escaping. It is

permissible in this application to use a shallow trap design

sometimes referred to as a running trap.

Cased Coil

3" MIN.

POSITIVE LIQUID SEAL

REQUIRED AT TRAP

Drain

Connection

2" MIN.

Figure 4

Condensate Drain Trap

The depth of a running trap (Figure 5) should be either 1" or a

depth that permits unrestricted condensate drainage without

excessive air discharge.

Field experience has shown condensate drain traps with an

open vertical Tee between the air handler and the condensate

drain trap can improve condensate drainage in some applica-

tions, but may cause excessive air discharge out of the open

Tee. The manufacturer does not prohibit this type of drain but

we also do not recommend it due to the resulting air leakage.

Regardless of the condensate drain design used, it is the

installer’s responsibility to ensure the condensate drain sys-

tem is of sufficient design to ensure proper condensate re-

moval from the coil drain pan.

PITCH

TOWARDS

DRAIN

1” MIN

TRAP

CONDENSATE

DRAIN CONN.

CONNECT DRAIN

SAME SIZE AS ON

UNIT OR LARGER

Figure 5

Running Trap

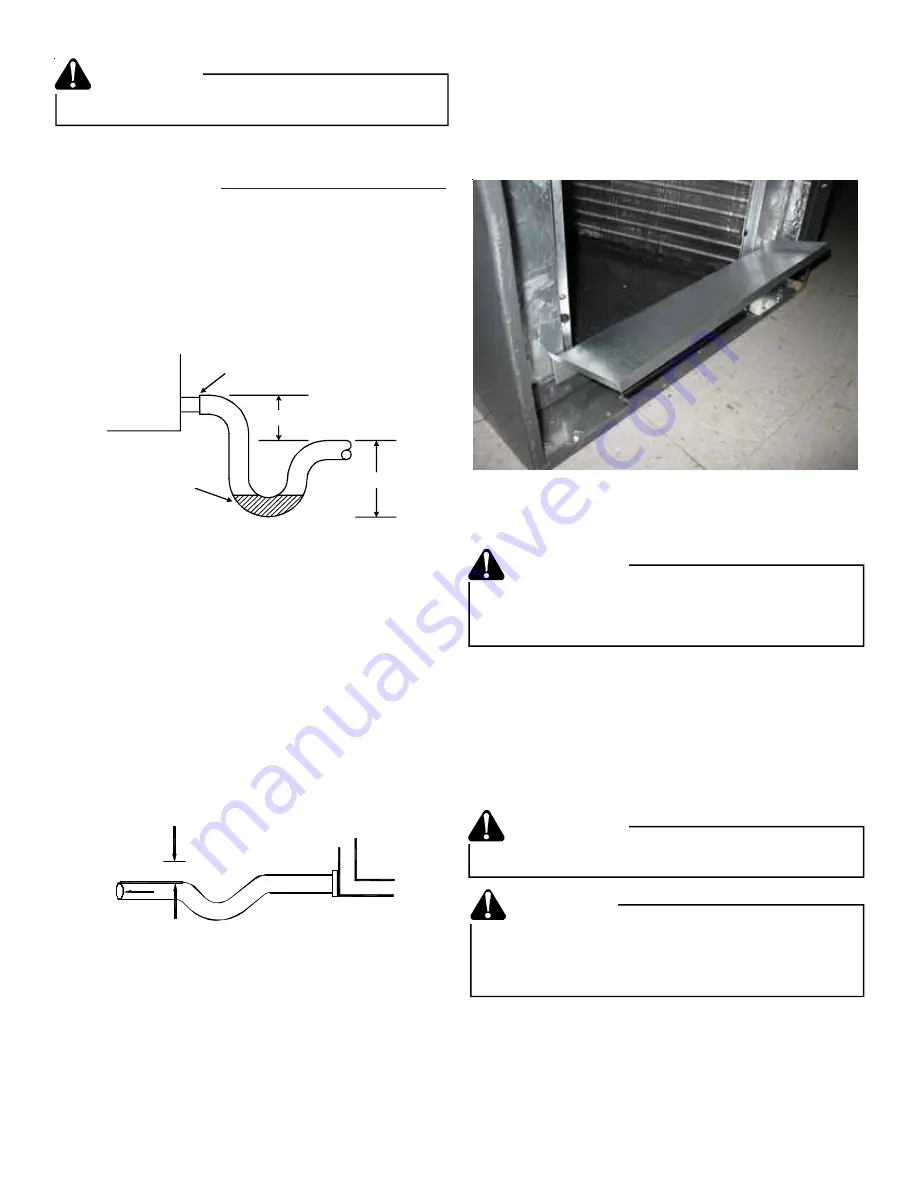

Horizontal Coil Water Blower-Off Bracket

CHPF4860 coils are shipped with an accessory kit containing

a sheet metal bracket. For horizontal-left applications where

the airflow may exceed 1600 CFM, this bracket must be

installed on the left side of the drain pan as shown in Figure 6.

Figure 6

Horizontal Blow-Off Bracket

Refrigerant Lines

A quenching cloth is strongly recommended to

prevent scorching or marring of the equipment

finish when welding close to the painted surfaces.

Use brazing alloy of 5% minimum silver content.

WARNING

All cut ends are to be round, burr free, and cleaned. Any other

condition increases the chance of a refrigerant leak. Use a

pipe cutter to remove the closed end of the spun closed suc-

tion line.

To avoid overheating after brazing, quench all welded joints

with water or a wet rag.

For the correct tubing size, follow the specification for the con-

denser/heat pump

The coil is shipped under pressure. Follow these

instructions to prevent injury.

WARNING

Applying too much heat to any tube can melt the tube. Torch

heat required to braze tubes of various sizes must be

proportional to the size of the tube. Service personnel must

use the appropriate heat level for the size of the tube being

brazed.

CAUTION

NOTE:

Tubes of smaller size require less heat to bring the

tube to brazing temperature before adding brazing alloy. The

use of a heat shield when brazing is recommended to avoid

burning the serial plate or the finish on the unit.