SYSTEM OPERATION

11

ADDITIONAL FILTERING ACCESSORIES

External Filter Rack Kit (EFR02)

The external filter rack kit is intended to provide a location

external to the furnace casing, for installation of a permanent

filter on upflow model furnaces. The rack is designed to mount

over the indoor blower compartment area of either side panel,

and provide filter retention as well as a location for attaching

return air ductwork.

Electronic Air Cleaner or Media Air Cleaner

The electronic air cleaner and media air cleaner are multi-

positional high efficiency air filtration devices that can be

installed in any position, except with the access door facing

down. The best location for the air cleaner is in the return

air duct next to the blower compartment. Before installing

the air cleaner, consider the application. The electronic air

cleaner must be readily accessible for periodic inspection and

cleaning of the pre-filters and electronic cells while the media

air cleaner must be readily accessible for periodic inspection

and replacement of the Media.

NORMAL SEQUENCE OF OPERATION

Power Up

•

120 VAC power applied to furnace.

•

Integrated ignition control performs internal checks.

•

LED light will flash once at power up and then remain on.

•

Integrated ignition control monitors safety circuit

continuously.

•

Furnace awaits call from thermostat.

Heating Mode

The normal operational sequence in heating mode is as

follows:

•

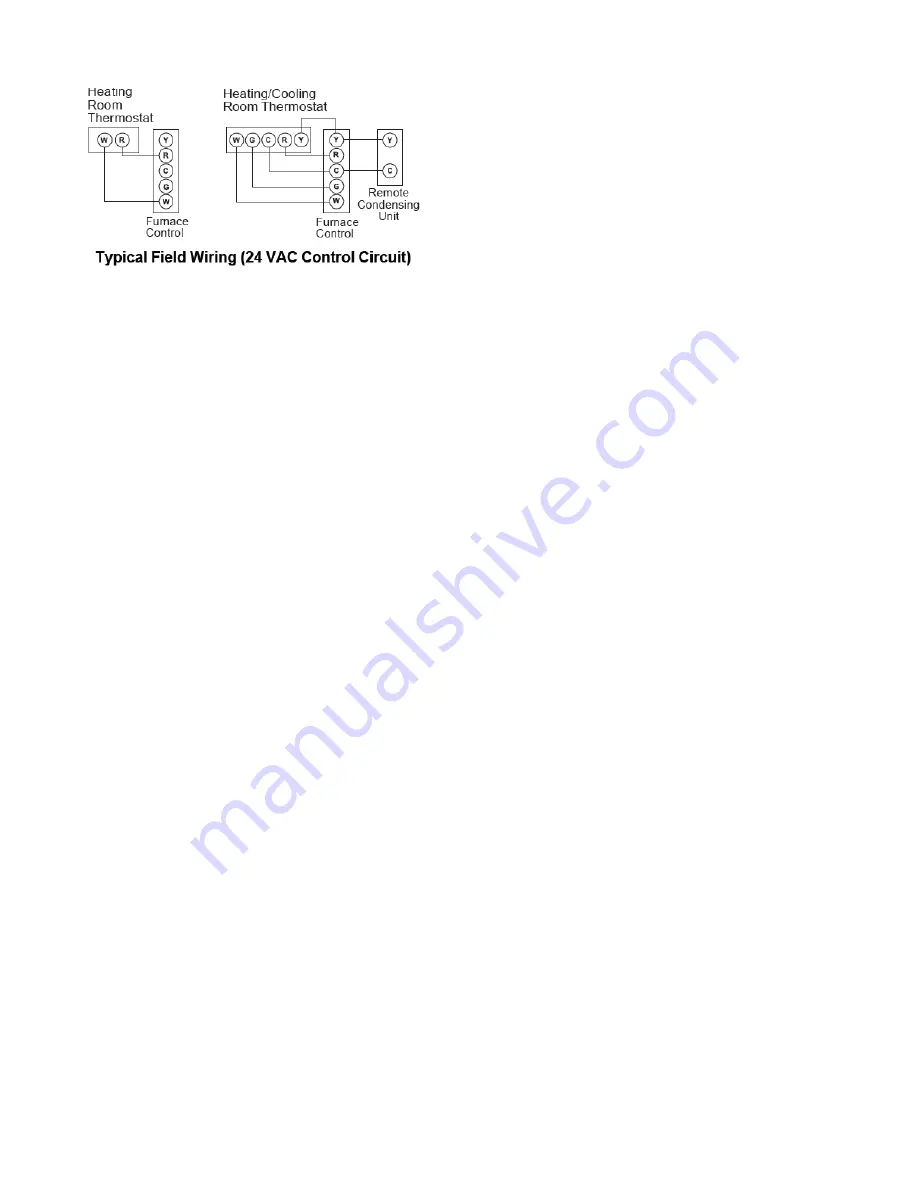

R and W thermostat contacts close, initiating a call for

heat.

•

Integrated control module performs safety circuit checks.

•

Pressure Sensor Verification:

The control operates

the inducer in a manner to verify the pressure sensor

null value and span operation are within specification.

If the system is operating correctly, this test takes only

a few seconds. If the system is not functioning properly,

the control times out after a maximum 90 seconds and

display the proper fault code.

•

Induced draft blower is energized for 30 second

prepurge.

•

Igniter warm up begins after 30 second prepurge expires.

•

Gas valves open at end of igniter warm up period,

delivering gas to burners and establishing flame.

•

Integrated control module monitors flame presence. Gas

valve will remain open only if flame is detected.

•

Circulator blower is energized on high heat speed

following a fixed 30 second blower on delay. Electronic

air cleaner terminals are energized with circulator blower.

•

Furnace operates; integrated control module monitors

safety circuits continuously.

•

R and W thermostat contacts open, completing the call

for heat.

•

Gas valve closes, extinguishing flame.

•

Induced draft blower is de-energized following a thirty

second post purge.

•

HUM terminal is de-energized.

•

Circulator blower continues running for selected heat off

delay period factory set at 120 seconds. If required this

can be changed in the field.

•

Electronic air cleaner is de-energized.

•

Furnace awaits the next call from thermostat.

Cooling Mode

The normal operational sequence in cooling mode is as

follows:

•

R, Y and G thermostat contacts close, initiating a call

for cool.

•

Integrated control module performs safety circuit checks.

•

Outdoor fan and compressor are energized.

•

Circulator blower is energized on cool speed following a

fixed six second on delay. If required this can be changed

in the field to 45 seconds. Electronic air cleaner terminals

are energized with circulator blower.

•

Furnace circulator blower and outdoor cooling unit

run, integrated control module monitors safety circuits

continuously.

•

R, Y and G thermostat contacts open, completing the

call for cool.

•

Outdoor fan and compressor are de-energized.

•

Circulator blower is de-energized following a fixed forty

firve second cool off delay period. Electronic air cleaner

terminals are de-energized.

•

Furnace awaits the next call from thermostat.

Fan Only Mode

The normal operational sequence in Fan Only Mode is as

follows:

•

R and G thermostat contacts close, initiating a call for

Summary of Contents for AMES960403BU AA

Page 25: ...TROUBLESHOOTING 25...

Page 26: ...TROUBLESHOOTING 26...