INSTALLATION CONSIDERATIONS

21

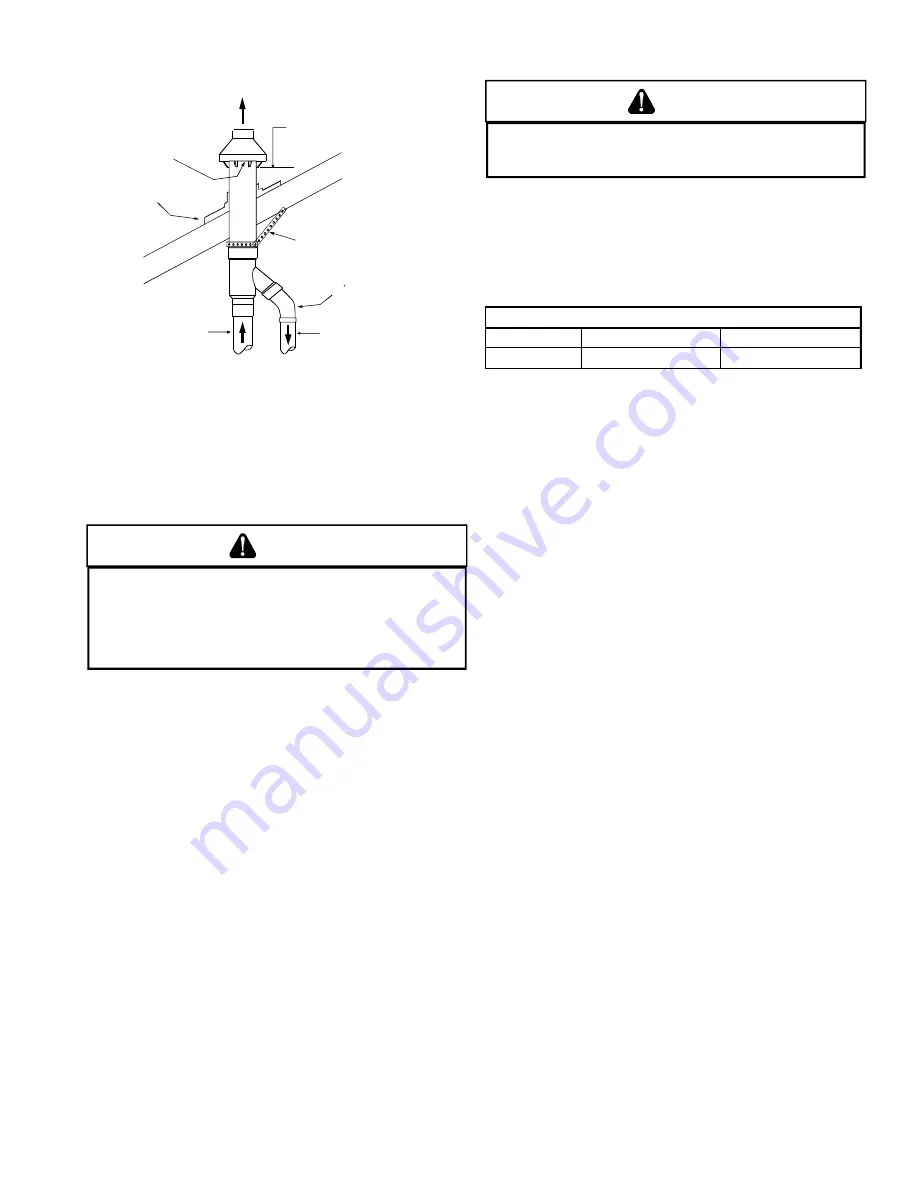

Vent

Maintain 12" (18" for Canada)

minimum clearance above highest

anticipated snow level. Maximum of

24" above roof.

Combustion Air

Roof Boot/Flashing

(Field Supplied)

Support (Field Supplied)

45 Elbow

(Field Supplied)

Combustion Air

Vent

Condensate Drain Lines and Drain Trap

A condensing gas furnace achieves its high level of efficiency

by extracting almost all of the heat from the products of

combustion and cooling them to the point where condensa-

tion takes place. The condensate which is generated must

be piped to an appropriate drain location.

WARNING

I

N UPRIGHT UPFLOW INSTALLATIONS, THE DRAIN TRAP MUST BE MOUNTED ON

THE OPPOSITE SIDE OF THE UNIT FROM THE JUNCTION BOX.

T

HIS WILL

REDUCE THE RISK OF WATER REACHING THE JUNCTION BOX IN THE EVENT OF

A BLOCKED DRAIN CONDITION.

F

AILURE TO FOLLOW THESE INSTRUCTIONS

CAN RESULT IN POSSIBLE PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH

DUE TO ELECTRICAL SHOCK.

•

If the drain line is routed through an area which may

see temperatures near or below freezing, precau-

tions must be taken to prevent condensate from

freezing within the drain line.

•

If an air conditioning coil is installed with the

furnace, a common drain may be used. An open

tee must be installed in the drain line, near the

cooling coil, to relieve positive air pressure from the

coil’s plenum. This is necessary to prohibit any

interference with the function of the furnace’s drain

trap.

GAS SUPPLY AND PIPING

The furnace rating plate includes the approved furnace gas

input rating and gas types. The furnace must be equipped to

operate on the type of gas applied. This includes any con-

version kits required for alternate fuels and/or high altitude.

CAUTION

T

O PREVENT UNRELIABLE OPERATION OR EQUIPMENT DAMAGE, THE INLET

GAS SUPPLY PRESSURE MUST BE AS SPECIFIED ON THE UNIT RATING PLATE

WITH ALL OTHER HOUSEHOLD GAS FIRED APPLIANCES OPERATING.

Inlet gas supply pressures must be maintained within the

ranges specified below. The supply pressure must be con-

stant and available with all other household gas fired appli-

ances operating. The minimum gas supply pressure must

be maintained to prevent unreliable ignition. The maximum

must not be exceeded to prevent unit overfiring.

Natural Gas

Minimum: 4.5" w.c.

Maximum: 10.0" w.c.

Propane Gas

Minimum: 11.0" w.c.

Maximum: 13.0" w.c.

INLET GAS SUPPLY PRESSURE

HIGH ALTITUDE DERATE

When this furnace is installed at high altitude, the appropri-

ate High Altitude orifice kit must be applied. This is re-

quired due to the natural reduction in the density of both

the gas fuel and combustion air as altitude increases. The

kit will provide the proper design certified input rate within

the specified altitude range.

High altitude kits are purchased according to the installa-

tion altitude and usage of either natural or propane gas.

Refer to the product Specification Sheet or Technical Manual

for a tabular listing of appropriate altitude ranges and corre-

sponding manufacturer’s high altitude (Natural, Propane gas,

and/or Pressure Switch) kits.

Do

not

derate the furnace by adjusting the manifold pres-

sure to a lower pressure than specified on the furnace rat-

ing plate. The combination of the lower air density and a

lower manifold pressure will prohibit the burner orifice from

drawing the proper amount of air into the burner. This may

cause incomplete combustion, flashback, and possible yel-

low tipping.

In some areas the gas supplier may artificially derate the

gas in an effort to compensate for the effects of altitude. If

the gas is artificially derated, the appropriate orifice size

must be determined based upon the BTU/ft

3

content of the

derated gas and the altitude. Refer to the National Fuel

Gas Code, NFPA 54/ANSI Z223.1, and information provided

by the gas supplier to determine the proper orifice size.

A different pressure switch may be required at high altitude

regardless of the BTU/ft

3

content of the fuel used. Refer to

the product Specification Sheet or Technical Manual for a

tabular listing of appropriate altitude ranges and correspond-

ing manufacturer’s pressure switch kits.