31

To adjust the circulator blower speed, proceed as follows:

1. Turn OFF power to the furnace.

2. Select the heating and cooling blower speeds that match

the installation requirements from the

airflow table in the

Specification Sheet

.

3. Relocate desired motor leads to the circulator blower heat

and cool speed terminals on the integrated control module.

(Terminals are identified as HEAT and COOL (hot)). If heating

and cooling blower speeds are the same, a jumper wire

must be used between the heat and cool terminals.

4. Connect all unused blower motor leads to the “PARK”

terminals on the integrated control module. Any leads not

connected to the “PARK” terminals must be taped.

5. Turn ON power to furnace.

6. Verify proper temperature rise as outlined in

Section XIV,

Startup Procedure and Adjustment - Temperature Rise

.

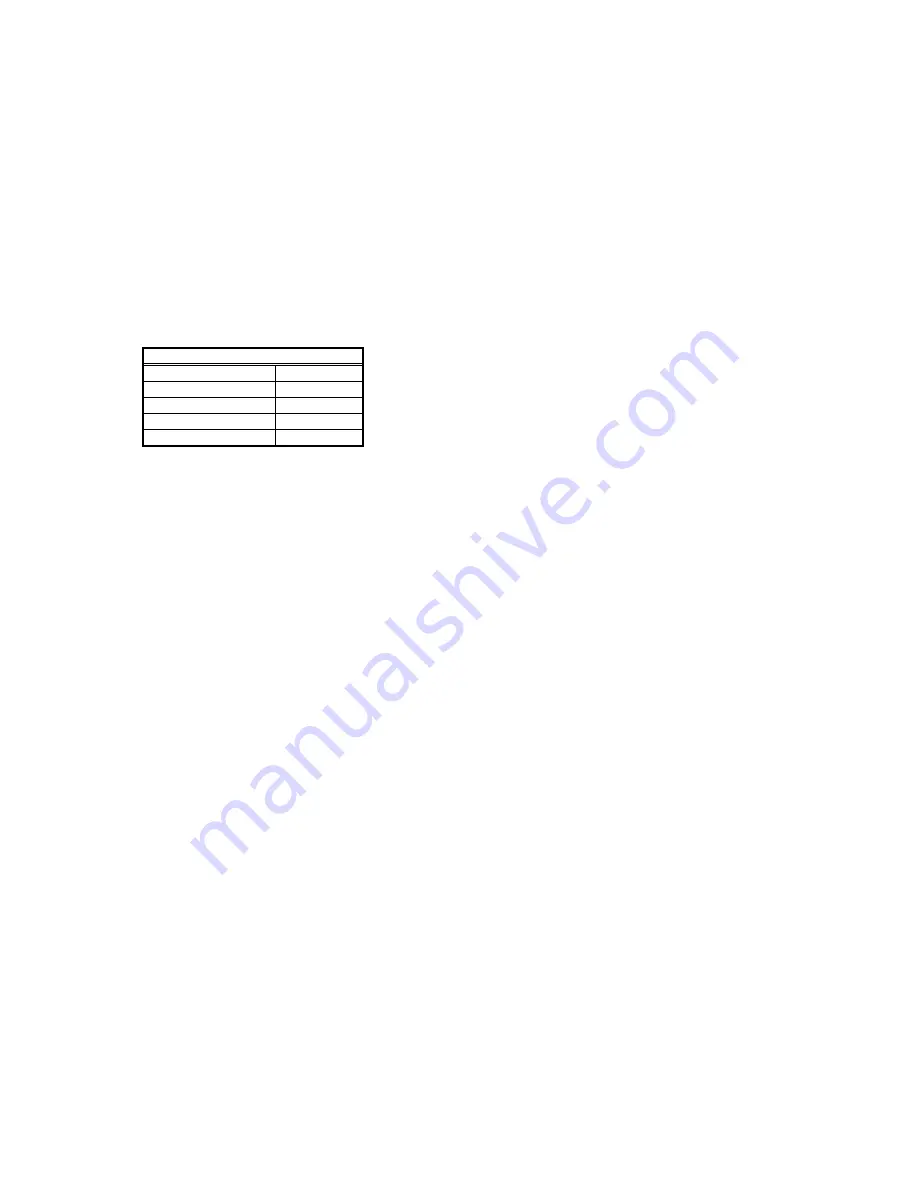

Orange

High

Common/Neutral

Medium Low

Circulator Blower Speeds

Low

Red

Medium Blue

Black

White

XV. NORMAL SEQUENCE OF OPERATION

P

OWER

U

P

The normal power up sequence is as follows:

•

115 VAC power applied to furnace.

•

Integrated control module performs internal checks.

•

Integrated control module LED will light.

•

Integrated control module monitors safety circuits

continuously.

•

Furnace awaits call from thermostat.

H

EATING

M

ODE

The normal operational sequence in heating mode is as follows:

•

R and W thermostat contacts close, initiating a call for heat.

•

Integrated control module performs safety circuit checks.

•

Induced draft blower is energized for 15 second prepurge

period causing pressure switch contacts to close.

•

Igniter warm up begins after 15 second prepurge expires.

•

Gas valve opens at end of igniter warm up period, delivering

gas to burners and establishing flame.

•

Integrated control module monitors flame presence. Gas

valve will remain open only if flame is sensed.

•

Circulator blower is energized on heat speed following a fixed

thirty second blower on delay.

•

Furnace runs, integrated control module monitors safety circuits

continuously.

•

R and W thermostat contacts open, completing the call for

heat.

•

Gas valve closes, extinguishing flame.

•

Induced draft blower is de-energized following a fifteen second

post purge.

•

Circulator blower is de-energized following the heat off delay

period (fixed 150 seconds).

•

Furnace awaits next call from thermostat.

C

OOLING

M

ODE

The normal operational sequence in cooling mode is as follows:

•

R and Y thermostat contacts close, initiating a call for cool.

•

Integrated control module performs safety circuit checks.

•

Outdoor fan and compressor are energized.

•

Circulator blower is energized on cool speed following a

fixed five second on delay.

•

Furnace circulator blower and outdoor cooling unit run,

integrated control module monitors safety circuits

continuously.

•

R and Y thermostat contacts open, completing the call for

cool.

•

Outdoor fan and compressor are de-energized.

•

Circulator blower is de-energized following a fixed forty five

second cool off delay period.

•

Furnace awaits next call from thermostat.

F

AN

O

NLY

M

ODE

The normal operational sequence in fan only mode is as follows:

•

R and G thermostat contacts close, initiating a call for fan.

•

Integrated control module performs safety circuit checks.

•

Circulator blower is energized on heat speed.

•

Circulator blower runs, integrated control module monitors

safety circuits continuously.

•

R and G thermostat contacts open, completing the call for

fan.

•

Circulator blower is de-energized.

•

Furnace awaits next call from thermostat.

XVI. OPERATIONAL CHECKS

B

URNER

F

LAME

The burner flames should be inspected with the burner compart-

ment door installed. A sight glass is provided for inspection pur-

poses. Flames should stable, quiet, soft, and blue (dust may

cause orange tips but they must not be yellow). Flames should

extend directly outward from the burners without curling, floating, or

lifting off. Flames must not impinge on the sides of the heat ex-

changer firing tubes.