RAIL SAW SR 310 H

OPERATION MANUAL

23

7

Maintenance

Proper, on schedule maintenance increases the service life of the machine, ensures availability and helps prevent unwanted

standstill. The components of the machine are subject to different maintenance intervals depending on the use. The maintenance

intervals must be determined by the system operator as part of the hazard evaluation and risk assessment. Observe the guidelines

in the applicable directives.

Service and maintenance measures are permitted only by qualified specialist companies.

Maintenance must be documented by the operator. It should be clear who carried out the work, when and where (proof of

maintenance).

Only original spare parts as well as suitable tools may be used:

-

The recommended maintenance intervals and inspection intervals are to be followed!

-

The causes of possible defects are looked for, e.g. damage, disturbing sounds, overheating, etc.

The machine must always be depressurized before maintenance work.

7.1

Recommended maintenance plan

Components for which wear and tear or even malfunction is determined during inspection, must be repaired or replaced at the

earliest possible date.

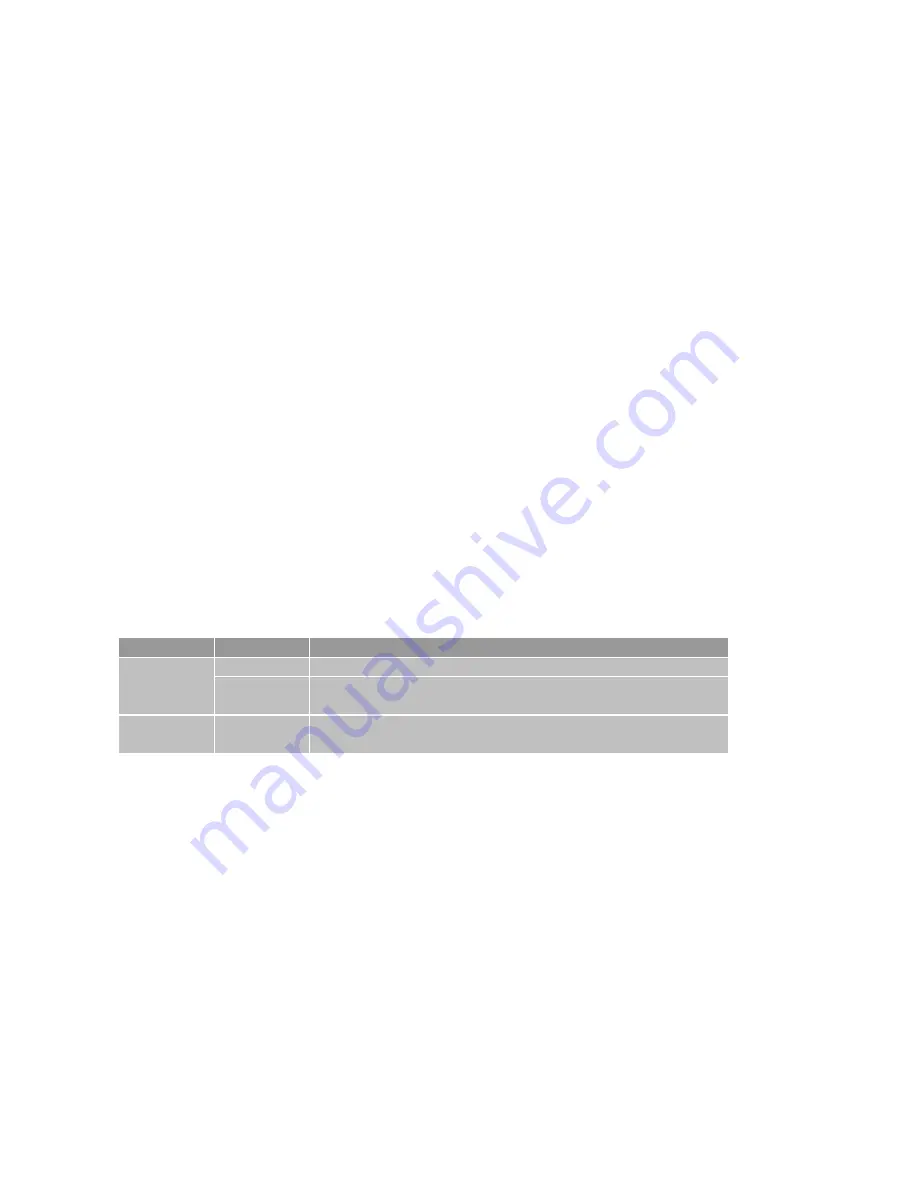

Components

Inspection

Intervals

Entire device

Cleaning

The entire device must be cleaned with a lint-free cloth at the end of the shift

Visual inspection

The entire device must be checked for damage daily. Damaged parts must be

replaced.

Hydraulic system Inspection

The hydraulic system must be checked for damage monthly. Damaged

components must be replaced.

Table 6: Maintenance plan

7.2

Change of hydraulic fluid

The hydraulic fluid must be replaced annually. Depending on usage and contamination, the hydraulic fluid may need to be replaced

at shorter intervals. Old hydraulic fluid must be disposed of properly. Refilling must be carried out via the the hydraulic unit. The

hydraulic unit is not contained in the scope of service of the machine. Old hydraulic fluid must be disposed of properly.