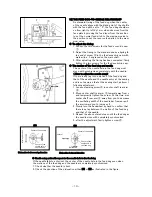

To adjust the position of the needle and shuttle

1. Loosen screw ⑤.

2. Loosen screw ⑥,and adjust so that marker dot Ⅲ

engraved on the eccentric cam of the vertical rod is

aligned with marker line Ⅳ engraved on the main shaft

Then, tighten screw ⑥.

3. Turn the handwheel toward you, and check the lifting

amount of the needle bar.

4. After the adjustment, securely tighten screws ⑤ and

⑥.

◆ The height of the needle bar

The correct height is that the distance from the blade point

of the shuttle to the upper end of the needle eyelet is 2.5 m

when the blade point of the shuttle is aligned with the cente

of the needle.

To adjust the height of the needle bar

1. Set the feed pitch to 0 mm.

2. Turn the handwheel and stop turning it when the blade

point of the shuttle is aligned with the center of needle.

3. Loosen screws ⑦.

4. Adjust the height by moving needle bar ⑧ up and down.

5. After adjustment has been completed, firmly tighten screw

⑦.

◆ The needle-to-shuttle clearance

The clearance between the recess in the needle and the

blade point of the shuttle has already been adjusted to 0.25

~0.35 mm.

Point of the shuttle has already been adjusted to 0.35 mm.

Adjust the clearance between the needle and the shuttle by

replacing the shuttle race back.

( The shuttle race back comes in six different thickness in

addition to the standard thickness. )

To repace the shuttle race back

1. Remove two screws ⑨ in the shuttle race, remove shuttl

race ⑩, and remove shuttle ⑪.

2. Turn the handwheel until shuttle driver ⑬ is brought to th

position where shuttle race back ⑫ comes off.

Then replace the shuttle race back.

⑥ Ⅲ Ⅳ

2.5mm

⑧

⑦

0.25~0.35mm

⑩

⑨

⑪

⑬

⑫

⑤

- 8 -

Summary of Contents for CS-471

Page 12: ...memo 13 ...