MAINTENANCE MANUAL

GP/146/99. Issue 9. October 2005

The silicon carbide ring fitted in the rear side of the HP impeller may be levered out,

by means of a small instrument screwdriver inserted between the ring and its rubber

cup.

Reassembly of the seal is completed as described below. Please note: Mechanical

Seals are precision engineered devices and extreme care must be taken to ensure

that no damage occurs to the lapped faces.

Read the fitting instructions before installation of the seal.

Ensure that the lapped faces are absolutely clean throughout the entire

installation.

Soiled faces must to be cleaned with appropriate degreasing cleaner

and soft tissue.

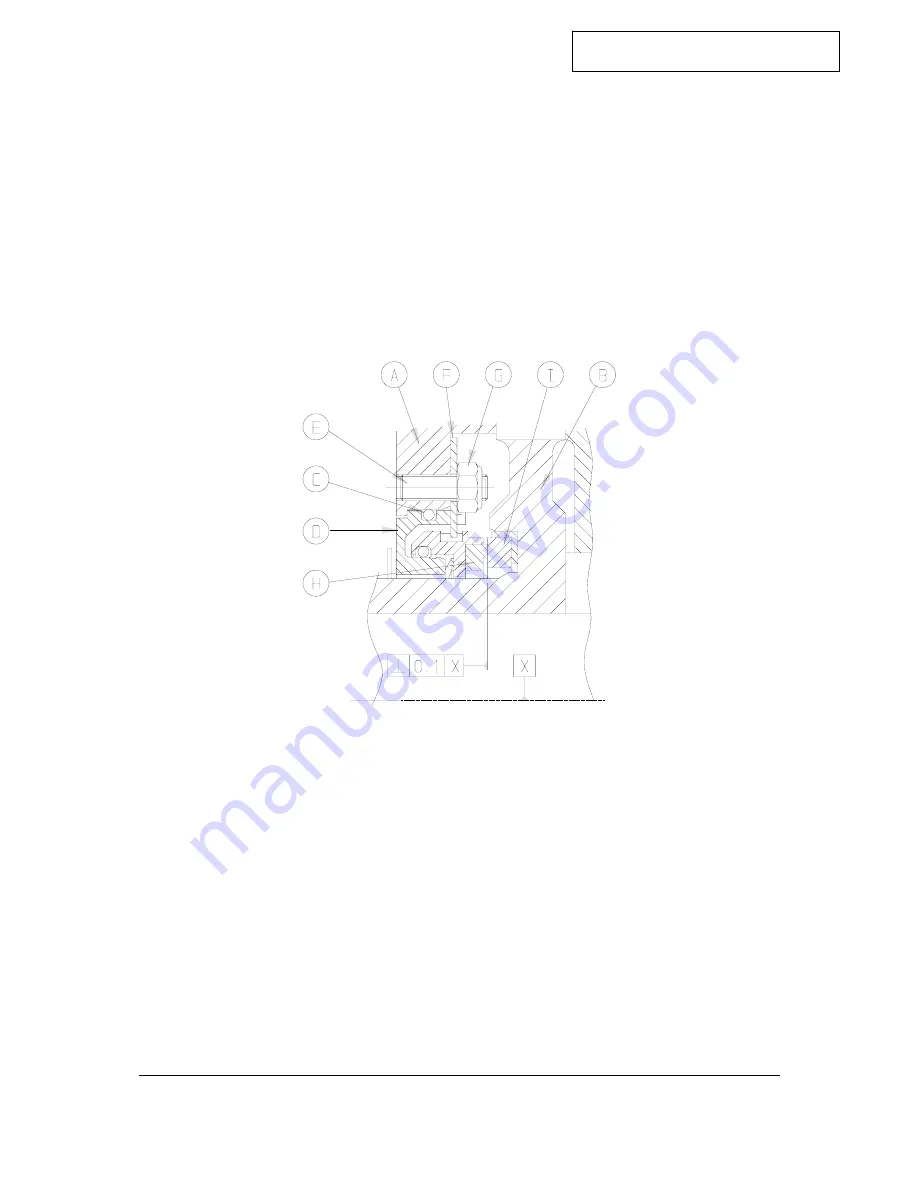

Fig 5-1Carbon seal

and seating assembly

1. Ensure that the Pump Body (A) and High Pressure Impeller (B) bores are clean

and free from burrs and sharp edges , see Fig 5-1.

2. Lubricate the O Ring (C) with a suitable lubricant and carefully assemble the

Seal Head Assembly (D) into the Pump Body (A), lining up the cutouts in the

Seal Head Assembly (D) with the threaded Studs (E).

3. Fit Washer (F) to each of the Studs (E) followed by the Lock Nuts (G). The lock

nuts should be tightened half a turn at a time so that the Seal Head Assembly

(D) is pulled squarely into the Engine Housing. Ensure that the Lock Nuts are

fully secured.

4. Ensure Carbon Face (H) is clean and free from grease, if not use a degreasing

cleaner and soft tissue. Apply clean water to the carbon face.

5. Take Impeller (B) and carefully push the Mating Ring Assembly (I) into the bore

using Fitting Tool Number 60275/08. Ensure that the Face of the Mating Ring

Assembly is fitted squarely in the impeller housing within 0.1mm.

6. Carefully fit the High Pressure Impeller onto the shaft and continue with pump

build.

©Hale Products Europe LTD, Warwick

GP/146/99

WTmaint - Issue9. 10-2005October 2005

17