22

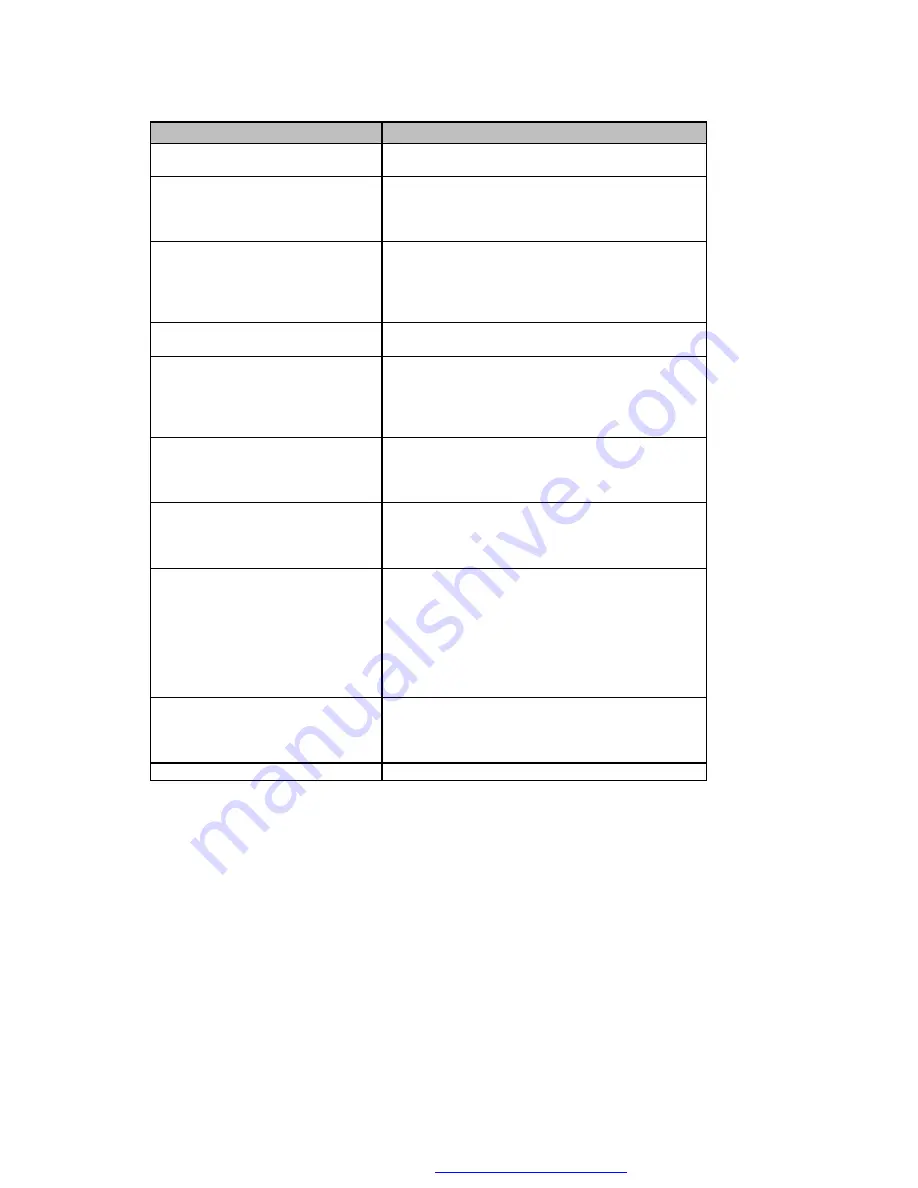

B. Troubleshooting

Problems

Recommended Solution

Power switch already turned on but

the LED does not light.

l

Check Power connector.

Printing stops and LED goes red.

l

Probably software setting or programming

problem.

l

Check to use the correct paper

l

Probably label jam, remove the stuck label

Printer is working but nothing is

printed on label.

l

Check the label is facing up and the paper you

use is thermal paper.

l

Check to choose the correct printer driver.

l

Make sure to choose the correct model of printer

on platen.

Label is stuck

l

Remove the stuck label and use soft cloth

soaked with alcohol to clean the adhesive glue.

Only part of the label got printed

l

Label is stuck on print head.

l

Probably software problem

l

Margins are not set properly

l

Printer head is not fixed in proper position,

re-positing printer head screws or clipper

Difficult to load label roll

l

Check if the label stuck on printer.

l

Remove the stuck label.

l

Make sure the width and thickness of label is

within the specification.

When printing out, some dots

missing

l

Clean printer head with alcohol. (If the label glue

is attached to printer head, please apply alcohol

to printer head; wipe with soft cloth softly.)

l

Replace printer head for possible damage.

Printing is not in the correct position

l

Check the Label Transmit Sensor, it may be

covered with dust.

l

Check with your label supplier; make sure they

have used the recommended backing material.

l

Adjust the label transmit sensor if you are an

experienced printer user.

l

Check the label guide, it may not be in the proper

position.

Label printing jumps to next label

l

Check if the label height setting is the same as

actual label height.

l

Check the Label Transmit sensor, it may be

covered with dust.

Printing is not very clear

l

Check the printer darkness setting.

Please call your agent for help if the above information can not help you.

PDF created with FinePrint pdfFactory trial version

http://www.fineprint.com