6

General Machine Products (KT), LLC

• 3111

Old Lincoln Hwy

•

Trevose, PA 19053

•

USA

TEL: +1

-

215

-

357

-

5500

•

FAX: +1

-

215

-

357

-

6216

•

www.gmptools.com

5.0 OPERATING PROCEDURE

IT IS IMPERATIVE THAT ALL PERSONS USING, OPERATING OR MAINTAINING THIS WINCH BE

FULLY TRAINED AND COMPETENT TO DO SO, AND HAVE READ THE ENTIRE OPERATING MANUAL.

GENERAL MACHINE PRODUCTS (KT), LLC CANNOT BE HELD RESPONSIBLE FOR MIS

-

USE OF THIS

EQUIPMENT.

To enable safe and trouble free operation the following points should be followed.

Prior to employing the winch for any hauling applications it is important to ensure that the winch is suita-

bly anchored to a Vehicle.

5.1

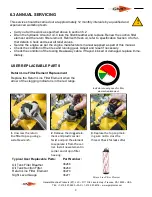

Ensure that the ball coupling and the center of the drum width is

oriented with the line of pull. See Fig 5.1. This ensures that reeling

of the rope takes place without undue pressure on the layering de-

vice and extends rope life.

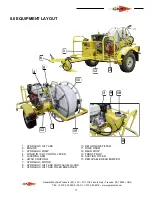

5.2 Vehicle Anchoring

-

Preferred method of anchoring

Align the winch as in 5.1 keeping the ball coupling securely attached

to the vehicle. Lower the rear prop legs and lift winch weight off

wheels onto legs and fix. Ensure winch is level from side to side.

5.3 Ground Rod Anchoring (if vehicle anchoring is not obtainable)

Lower the rear prop legs and front prop to the ground, such that the winch is level from side to side and

the weight is off the wheels. Drive a ground anchor through each chassis anchor bracket at the tow eye

end of the chassis, See Fig 5.3A, The quality of the ground needs to be assessed with regards suitability

for winch anchoring prior to winch operation.

5.4 Loading/Unloading drums

To load/unload a drum it is necessary to remove the rear spool guard. This

should be stored in a suitable place and re

-

fitted when the trailer is to be

used in transit again. Open the split bearing and slide the drum to the right.

Lift the drum vertically initially favoring the side with the split bearing. Re-

verse to install.

Remove pins and remove spool guard

Open split bearing

Slide drum out of coupling

Remove drum

Fig 5.3A

Fig 5.1