8

General Machine Products (KT), LLC

• 3111

Old Lincoln Hwy

•

Trevose, PA 19053

•

USA

TEL: +1

-

215

-

357

-

5500

•

FAX: +1

-

215

-

357

-

6216

•

www.gmptools.com

6.0 MAINTENANCE

IT IS IMPERATIVE THAT ALL PERSONS USING, OPERATING OR MAINTAINING THIS WINCH BE FUL-

LY TRAINED AND COMPETENT TO DO SO, AND HAVE READ THE ENTIRE OPERATING MANUAL.

GMP CANNOT BE HELD RESPONSIBLE FOR MIS

-

USE OF THIS EQUIPMENT.

It is recommended that this winch is serviced every 12 months, regardless of its condition or

the number of operating hours used. This will help to ensure reliable, trouble free service.

6.1 PRE

-

WINCHING MAINTENANCE CHECK

This should be carried out each day prior to the start of winching.

•

Check hydraulic oil level. Oil should be visible within the black lines marked on the oil level sight

gauge. Replenish if necessary with the correct grade of hydraulic oil to suit the climatic conditions.

(Refer to the section 4 for grades of hydraulic oil required)

•

Check the engine oil level as indicated in the Engine Operating Manual. Replenish if necessary.

•

Check that there is enough fuel in the tank to complete the planned winching schedule.

•

Check the condition of the hydraulic hoses, replace if damaged.

•

Check that the drum arm split bearing is clean and lightly greased.

•

Check that the drum shaft bearing spigot is clean.

•

Check the tire condition and tire pressures, refer to section 4 of details.

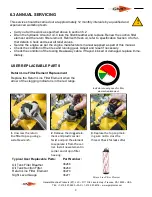

b) MONTHLY MAINTENANCE

•

This should be carried out at intervals not exceeding 12 weeks.

These intervals will

depend upon the degree of use of the winch.

•

Carry out all the pre

-

winching checks as detailed above.

•

Apply a general purpose, medium grade grease to the towing hitch grease nipples (if applicable)

and also to the towing ball up if fitted.

•

With the engine and drum running, check the return filter condition indicator. This is red/green

indicator mounted on the hydraulic oil tank filter. If the indicator is well over into the red area, re-

place the filter.

•

Apply grease to the layering arm spindle.

!

!