Supplied By www.heating spares.co Tel. 0161 620 6677

9

220562A

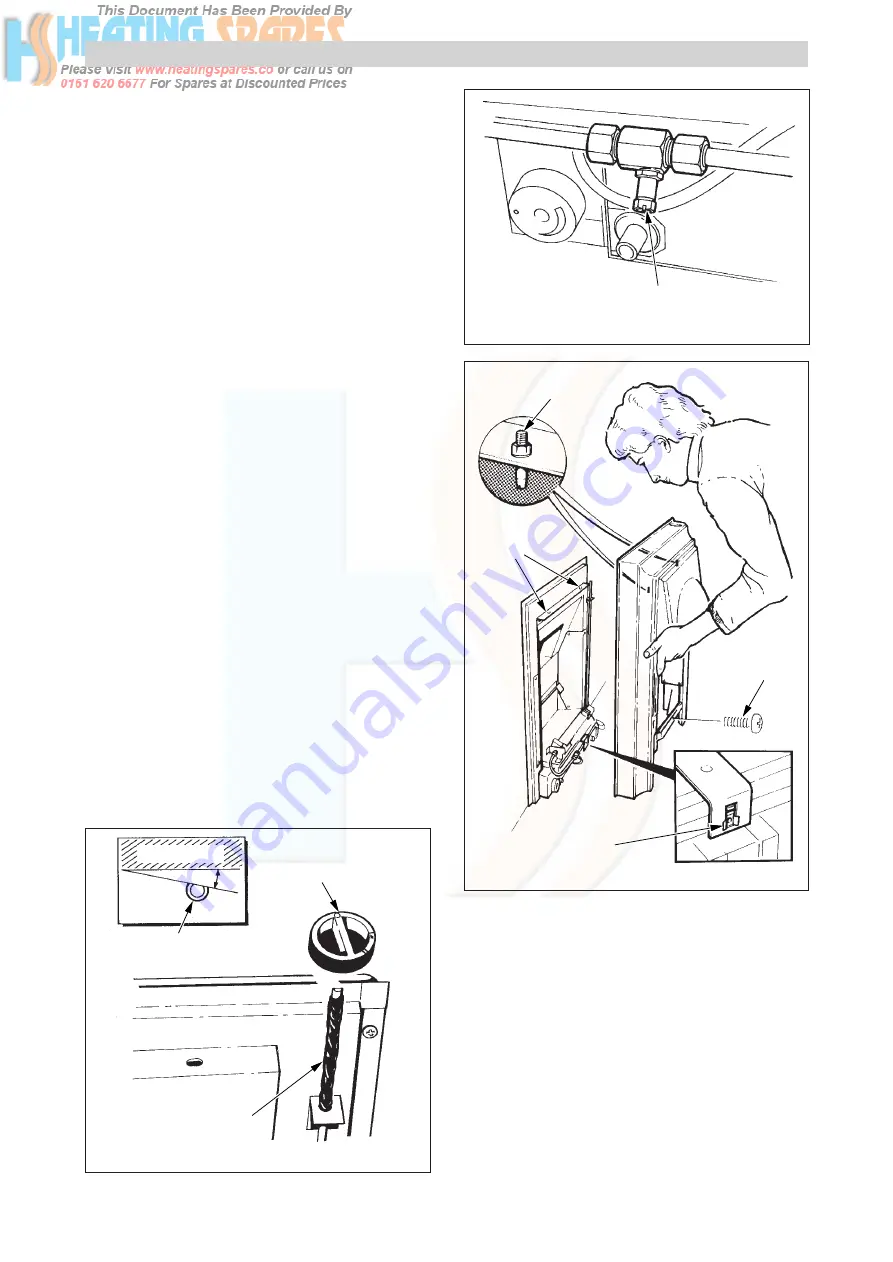

5 L i g h t i n g , T e s t i n g a n d F i t t i n g I n t e r n a l P a r t s .

Diagram 5.1

Air may be present in the supply to the fire so that the

initial lighting operation may need to be repeated.

With the burner lit. Check joints at all tap positions for

gas soundness in accordance with the current issue of

BS6891.

To change settings, refer to diagram 5.4.

Check that the gas pressure is as stated in the Data

Section or on the Data Label.

If there is any doubt about the gas rate, check at the

meter, having turned off all other gas appliances and

pilot lights.

The gas rate for this fire front is about 0.63m

3

/h

(17.75ft

3

/h), equal to, after 10 minutes, about 3 minutes

23 seconds for 1ft

3

.

Push in and turn the control knob fully clockwise to turn

off, remove the pressure gauge, replace the test nipple

screw and ensure that a gas tight seal is made.

5.2 Fire Front

Remove the castings from the packaging.

Lift the fire front up, take care as it is heavy, and slide it

down to locate the pins into the brackets, see

diagram 5.3.

Secure the fire front to the combustion chamber

assembly (base), using the M4 screw provided in the

loose items pack, see diagram 5.3.

WALL LINE

12˚

DRIVE ROD

Flat facing the wall

INSULATION SLEEVE

CONTROL KNOB

3517

Diagram 5.2

PRESSURE

TEST POINT

4020

Diagram 5.3

4017

LOCATION

PEG (2)

LOCATION

HOLES

FIRE

FRONT

SECURING

SCREW

FIRE FRONT

RETAINING

NUT