14

Installation/Operation & Maintenance Manual

GM

-

6140H 2-POST LIFT

◆

Install the safety devices.

◆

Adjust both cables and keep the carriage in

balance.

◆

Screw the joint of the high-pressure hose and

fix it on the base.

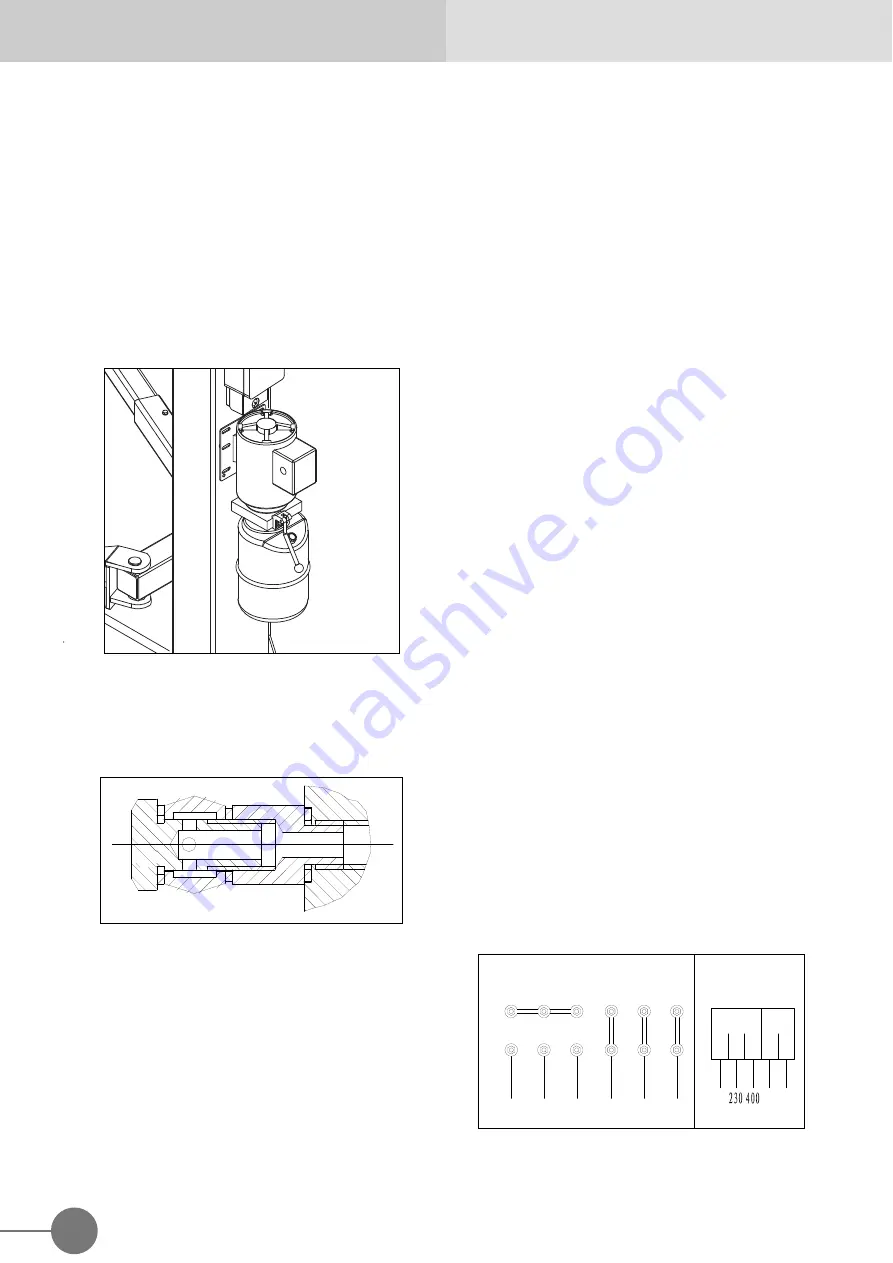

4.4.2 HYDRAULIC PALNT

◆

Install the pump on the hock board according to

Fig. 34

and fix it on the bottom of main column.

Fig. 34

◆

Connect the hydraulic unit to the circuit crossing

with a flexible pipe.

(Fig. 35)

Fig. 35

◆

Tight all the fittings very well, even the one

already mounted by the manufacturer.

◆

Fill the hydraulic unit tank with 8 liters of

hydraulic oil ISO 32 as IP HYDRUS OIL 32,

SHELL TELLUS OIL T32 or similar

(See

Chapter 2, TECHNICAL SPECIFICATIONS)

.

◆

Remove the oil filling cap and substitute it with

the given drain cap.

4.4.3 ELECTRIC PLANT CONNECTION

WARNING

The operations listed below must be performed

by skilled personnel.

4.4.3.1

Before connecting the electric system, make

sure that:

◆

The power supply plant to the lift is equipped

with the protection device required by current

standards in the country where the machinery is

installed.

◆

The power supply line has the following cross-

section:

Lift voltage 400V, three-

phase………….……Min.

2.5mm

2

Lift voltage 230V, three-

phase…………………Min.

4mm

2

Lift voltage 230V, single-

phase……………..…Min.

6mm

2

◆

The voltage oscillations are within the tolerance

range set forth by the specifications.

The manufacturer supplies the rack to operate at

400V with a three-phase configuration; if the line

voltage is different, the motor and transformer

connection must be changed.

(Fig. 36)

It is also

necessary to replace the thermal relay requesting

that part from the manufacture and/or service

center.

Fig. 36

W2

U2

V2

W1

V1

U1

L1

L2

L3

U2

W2

V2

W1

V1

U1

L3

L2

L1

Motor

0

0 24

Trasformer

Summary of Contents for GM - 6140H

Page 27: ......