3

Bench Top Drill Press

1. Install the machine on a flat, level bench top that is sturdy enough to support the weight and vibrations of

the drill press.

2. Always wear protective safety glasses or goggles when operating the machine.

3. Clear woodchips, sawdust and metal chips before operation.

4. Make sure head and table supports are secure before drilling

5. Check all nuts, bolts and screws for tightness regularly. Vibration during operation may cause hardware to

loosen.

6. Use the correct drill bit. Ensure that you have selected the correct drill bit and drill speed based on the

workpiece's material and thickness. Ensure that there are no nails or other hard objects in the path of the

drill bit. Take care not to force the drill bit, you may permantly damage the bit and the workpiece.

7. Do not use a drill bit longer than 175mm (150mm outside chuck jaws).

8. Do not place drill bit against workpiece before turning power switch on. Turn on the drill before and allow

the bit to come up to full speed before drilling.

9. Make sure you are drilling at the correct speed based on hole size and workpiece material.

10. Make sure there are no nails or other hard obstacles in the way of the drill bit inside the workpiece

11. Jog the motor before drilling to ensure that drill bit is secure and motor is in working order.

12. Hold workpiece securely at a safe distance from the drill bit or use clamps or vise. Never drill into an

unsecured workpiece.

OPERATION INSTRUCTIONS

OPERATION INSTRUCTIONS

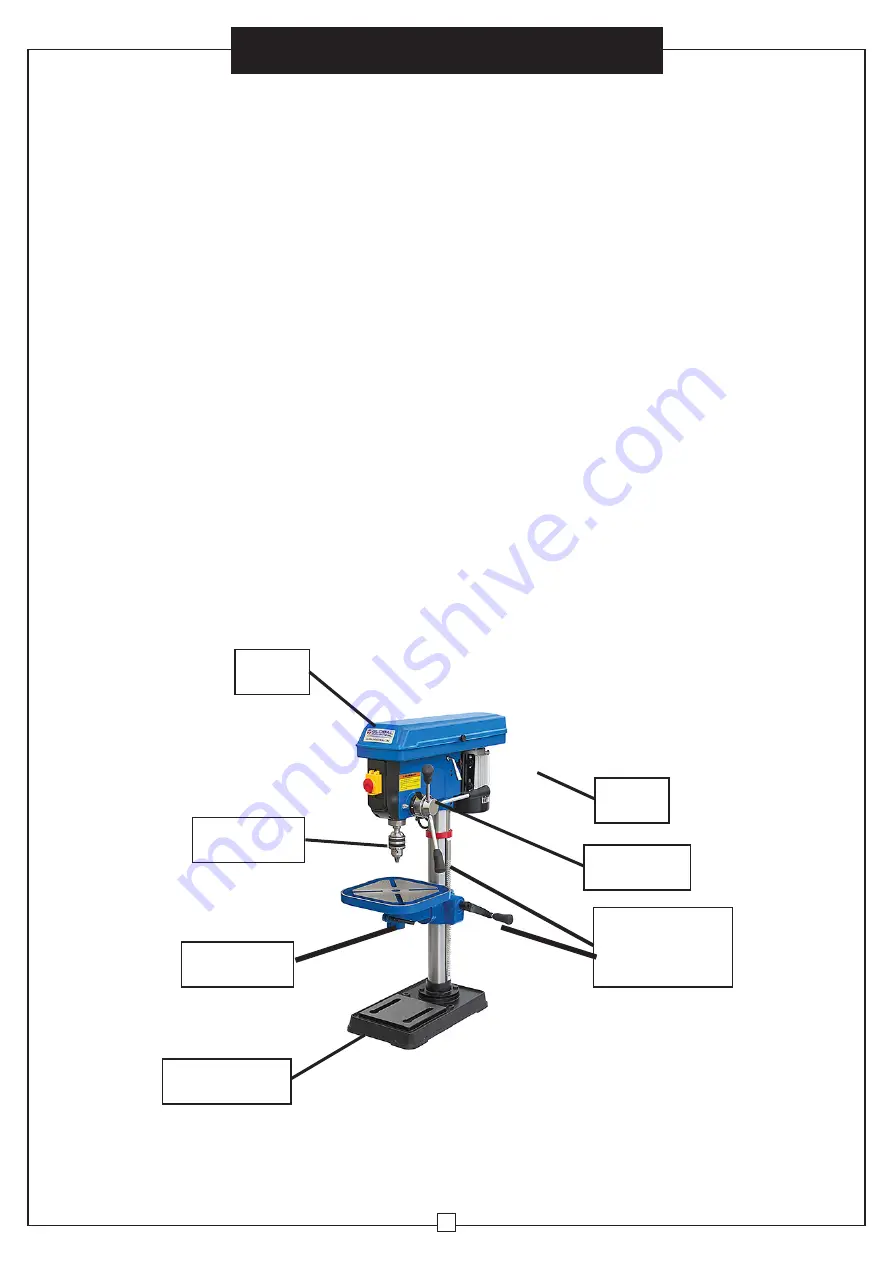

Head

Drill Chuck

Motor

Feed Crank

Lifting Rack

and Crank

Base Platform

Work Table