Page 23

Your Stainless Lite unvented cylinder is automatic in normal use, but requires routine

maintenance which is normally carried out at least annually along with the boiler

service. The maintenance must be carried out by a suitably competent tradesperson

who is qualified to work on unvented cylinders. The checks/work needed are listed

in the maintenance part of these Instructions.

The control thermostat of the immersion heaters for direct heating of our cylinders

are set at 60°C. The control thermostat for indirect heat exchanger heat up of our

cylinders are usually set at between 60°C - 65°C. During commissioning the actual

temperature that the cylinder reaches when the thermostat(s) operate should be

tested and adjusted so that it achieves a minimum of 60°C, in order to comply with

the Legionella pasteurisation requirements.

When initially opening the taps, a small surge in flow may be experienced, which

disappears as the pressure in the system stabilises. This is quite normal with these

types of systems and does not indicate a fault.

In some areas the water will initially appear cloudy, but will quickly clear when left

to stand. This is nothing to be concerned about and is due to aeration of the water.

WARNING

- If water is seen flowing through the tundish, this indicates a fault condition

which needs action.

If the discharge is hot and continuous, turn the boiler and/or the immersion heaters

off, but do not turn off the cold water to the appliance until the discharge is cold.

Note:

The discharge may stop by itself as the discharge cools.

If the discharge is cold and intermittent, no immediate action is needed but this

indicates a problem with the expansion vessel.

However, in both cases you must call the registered installer / a suitably qualified,

competent tradesperson, advise them that you have an unvented cylinder and

request a maintenance visit.

DO NOT,

at any time, tamper in any way with the safety valves or overheat thermostats/

wiring.

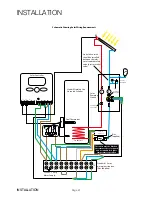

INSTALLATION

USER INSTRUCTIONS