Page 14

15 mm

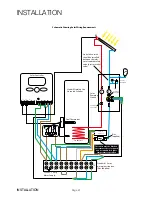

discharge

pipe

Expansion

relief valve

Typical Discharge Pipe Arrangement

Dotted line showing

alternative route with

single tundish being used

600 mm max.

P & T

Relief

Valve

300 mm

min.

22 mm metal pipe with continuous

fall up to 9m equivalent length (D2).

NOTES:

The discharge will consist of scalding

waterand steam. Asphalt, roofing felt

and non-metallic rainwater goods may

be damaged by such discharges.

It is not acceptable to discharge straight

into a soil pipe.

Discharge below

fixed grating

Fixed Grating

Trapped gully

Pressure & Temperature/expansion Relief

Valve Pipework

The relief valve should be installed to discharge

in accordance with G3 of the Approved

Document of the Building Regulations and

should be piped to where it is visible, but will

not cause danger to persons or damage to

materials.

The following information is taken from

Approved Document G3 of the Building

Regulations and is provided to assist with

the design and installation of the discharge

pipework. However, the information is not

exhaustive and reference should always be

made to Approved Document G3 of the Building

Regulations. The final decision regarding any

arrangements rests with Building Control and

it is recommended that their advice is sought

if you have any concerns regarding this aspect

of the installation.

The two safety valves will only discharge

water under fault conditions. When operating

normally water will not be discharged.

The tundish should be vertical, located in the

same space as the unvented hot water storage

system and be fitted as close as possible and

within 600mm of the safety device e.g. the

temperature relief valve.

The discharge pipe (D2) from the tundish should

terminate in a safe place where there is no risk

to persons in the vicinity of the discharge, be

of metal and:

a) Be at least one pipe size larger than the

nominal outlet size of the safety device unless

its total equivalent hydraulic resistance

exceeds that of a straight pipe 9m long

i.e. discharge pipes between 9m and 18m

equivalent resistance length should be at

least two sizes larger than the nominal outlet

size of the safety device, between 18 and

27m at least 3 sizes larger, and so on. Bends

must be taken into account in calculating

the flow resistance. Refer to the table and

the worked example.

An alternative approach for sizing discharge

pipes would be to follow BS EN 806-2:2005

Specification for design installation, testing

and maintenance of services supplying water

for domestic use within buildings and their

curtilages.

b) Have a vertical section of pipe at least

300mm long, below the tundish before any

elbows or bends in the pipe work.

c) Be installed with a continuous fall.

Worked Example

The example below is for G1/2 temperature relief valve with a discharge pipe (D2)

having 4 elbows and length of 7m from the tundish to the point of discharge.

From the table below:

Maximum resistance allowed for a straight length of 22mm copper discharge

pipe (D2) from a G1/2 temperature relief valve is: 9m subtract the resistance for

4 x 22mm elbows at 0.8m each = 3.2m.

Therefore the maximum permitted length equates to: 5.8m.

5.8m is less than the actual length of 7m therefore calculate the next largest size.

Maximum resistance allowed for a straight length of 28mm pipe (D2) from a G1/2

temperature relief valve equates to: 14m.

As the actual length is 7m, a 28mm (D2) copper pipe will be satisfactory.

Sizing of copper discharge pipe ‘D2’ for a temperature relief valve

with a G1/2 outlet size (as supplied)

Size of discharge

pipework

Maximum length of

straight pipe

(no bends or elbows)

Deduct the figure

below from the

maximum length for

each bend or elbow in

the discharge pipe

22mm

Up to 9m

0.8m

28mm

Up to 18m

1m

35mm

Up to 27m

1.4m

INSTALLATION

INSTALLATION