Page 33

mCHP

BOILERMA

TE

A-CL

ASS

COMMISSIONING 6.0

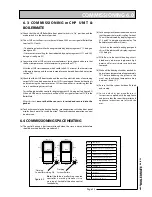

6.3 COMMISSIONING mCHP UNIT &

BOILERMATE

(a) Check that the mCHP BoilerMate front panel switch is in ‘On’ position and the

mode switch is in the ‘normal’ position.

(b) The mCHP unit will not start i.e there will be no 240V ac start signal at BoilerMate

terminal ‘SL-O’ until:-

• The heating clock calls for heating indicated by display segment V1.1 being on

(see figure 6.2)

• Store sensors are calling for heat indicated by display segments H1.1 and H1.2

being on (see figure 6.2)

(c) Commission the mCHP unit as per manufacturer’s instructions and ensure that

the flow temperature is set at maximum i.e. greater than 77

o

C.

After the mCHP start sequence, which could take 8 - 12 minutes, the thermal store

will begin to heat up and the store temperature can be read from the display (see

section 3.6)

(d) Check that the mCHP boost mode and the auxiliary electric heater is functioning

correctly. This can be done when the mCHP is running and the central heating is

on by removing the top store sensor, S6 from the pocket i.e. simulating that the

store is not heating at correct rate.

This will be indicated by controller display segment H2.2 being on (See figure 6.2).

When mCHP boost is active, there will be a 230V ac signal at terminal ‘SL-B’ in the

BoilerMate.

After this test,

ensure that the sensor is inserted and secured into the

pocket.

(e) To check manual electric backup heating , move operation switch on front panel

display from ‘normal’ to ‘switch’ position. The electric backup operation can now

be observed.

6.4 COMMISSIONING SPACE HEATING

(a) The central heating is best commissioned when the store is hot and therefore

should be carried out after procedure 6.3.

(b) Set heating clock to continuous and ensure

that the room thermostat is calling for heat.

This will be indicated by display segments

V1.3 and V1.4 being on respectiveley. The

BoilerMate controller will now:-

• Switch on the central heating pump and

this will be indicated by display segment

H2.2 being lit.

(c) With flow to the central heating circuit,

bleed every radiator and pipework high

points until air or air/water mix has been

removed.

(d) Wait until the heating circuit has reached its

normal mean temperature of approximately

75

o

C before balancing the system in the

usual way to achieve a temperature drop

between 10 and 12

o

C.

(e) Ensure that the system has been flushed

and treated.

(f) Set the clock as per manufacturer’s

instructions supplied with the appliance

and ensure that the room thermostat and

appliance instructions are left with the

user.

LED

Description

H1.1

Middle store sensor calling for heat

H1.2

Bottom store sensor calling for heat

H1.3

Spare

V1.1

HW Programmer calling for heat

V1.3

CH Programmer calling for heat

V1.4

Room thermostat calling for heat

H2.1

PHE pump on

H2.2

CH Pump on

H2.3

mCHP/System pump on

V2.1

mCHP on

V2.2

Switch on / electric boost on

V2.4

mCHP boost mode on

Note:

if both ‘dots’ are flashing then the

controller is working. However it is a

warning of limited/alternative control

functionality

@&LASHING

,OCKOUT&AILURE

@&LASHING

#ONTROLLERW

(

6

6

(

(

6

6

(

6

6

(

(

6

6

Figure 6.2

Summary of Contents for mCHP BMA 225

Page 44: ......