Page 28

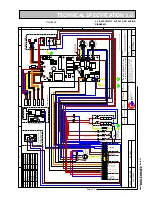

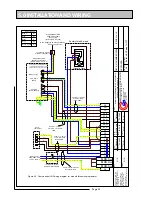

5.0 INSTALLATION AND WIRING

5.3

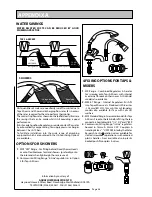

PIPEWORK CONNECTION

(a) The position of the pipework connections is shown

opposite in figure 5.3 the connection sizes and

dimensions are shown in figure3.2 and Table 3.1.

All connections are also labelled on the appliance.

it is essential that the pipework is connected to the

correct connection.

(b) if using pushfit connections with the flexible

hose kits, it is important to check that they are

compatible. Written approvals have already been

obtained for: -

•

Hepworth – Hep

2

O BiTite

•

John Guest – Speedfit

•

Yorkshire – Tectite

However similar assurances cannot be obtained

for Polypipe fittings and therefore we can not

recommend their use.

(d) All factory made joints should be checked after

installation in case they have been loosened during

transit.

(e) The fittings for the feed and expansion cistern

should be installed following the instructions

provided by the manufacturer in a position to

suit the particular location and the cistern fitted

on its support base. The cold feed/expansion and

safety open vent should be installed between the

appliance and the feed and the expansion cistern.

NOTE:

2 F&E cisterns are provided with the 235

model. The ballvalve should not be fitted in the

same cistern as the cold feed connection and the

position of these and the interconnecting pipework

should be arranged to reduce the possibility of

stagnant pockets of water in the cisterns.

(f) it is normally envisaged that the feed and expansion

cistern will be located in the same cupboard as the

BoilerMate itself to maintain dry roof space. However

if it is necessary to locate the cistern in the roof

space (or on a higher floor) the cold feed/open vent

pipework and the cistern will need to be adequately

insulated and protected against frost damage.

(g) No valves should be fitted in the safety open vent

which must be a minimum of 22mm copper pipe

or equivalent.

(h) The overflow/warning pipe shall have a continuous

fall, be fitted to discharge clear of the building and

be sited so that any overflow can be easily observed.

it shall also be installed in a size and material

suitable for use with heating feed and expansion

cisterns in accordance with BS 5449 and should not

have any other connections to it.

(i)

NOTE:

Combined feed and open vent pipe

arrangement must not be used.

FiG 5.3

Summary of Contents for mCHP BMA 225

Page 44: ......