Page 31

LED

Description

LED

Description

H1.1

Middle store sensor calling for heat

H2.1

PHE pump on

H1.2

Bottom store sensor calling for heat

H2.2

3 port valve on (for heating)

H1.3

Spare

H2.3

Boiler/heating system pump on

V1.1

HW Programmer calling for heat

V2.1

Boiler on

V1.3

CH Programmer calling for heat

V2.2

Switch on / electric boost on

V1.4

Room thermostat calling for heat

V2.4

Boiler boost mode on

Note: If both ‘dots’ are flashing then the controller is working. However it is a warning

of limited/alternative control functionality

‘Flashing’

Lockout/Failure

‘Flashing’

Controller working OK

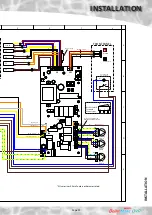

H1.3

V1.3

V1.4

H1.2

H1.1

V1.1

V1.2

H2.3

V2.3

V2.4

H2.2

H2.1

V2.1

V2.2

COMMISSIONING

INSTALLATION

Once the system is finally filled turn down the servicing valve for the ballvalve

in the F & E cistern to the point where the warning/overflow will cope with the

discharge arising from a ballvalve failure.

Cleansing Hot/Cold Water System Treatment

Fully flush and if necessary chlorinate the hot and cold water system in accordance

with the recommendations in the Model Water Byelaws and BS 6700.

Note: Incorrect chlorination will damage the plate heat exchanger so care must

be taken that the system is fully flushed.

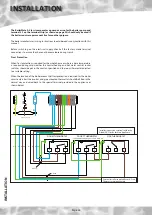

Commissioning the BoilerMate control system

For maximum system efficiency the store thermostat must be in control of the boiler

i.e. the boiler cycles on the store thermostat and not on its integral thermostat. The

BoilerMate control system will automatically commission itself to match the actual

performance of the installed boiler. However the operation of the control system

should be checked as follows.

(a) Check that the BoilerMate front panel mode

rocker is in the ‘normal’ position. Put the

hot water control rocker in the constant

position and the central heating control

rocker in the off position.

(b) The boiler will not start i.e there will be no

240V ac start signal at BoilerMate terminal

‘SL-B’ until:-

• The heating programmer calls for hot

water /heating which will bring display

segment V1.1 on, and

• Store sensors are calling for heat which

will bring display segments H1.1 and H1.2

on (see opposite)

(c) Set the boiler thermostat to maximum and

commission the boiler as per manufacturer’s

instructions and ensure that the flow

temperature reaches more than 77

o

C before

switching off. Display segments H2.3 and

V2.1 will be on whilst the boiler is firing.

(d) Check and adjust the speed of the boiler

pump to provide a differential temperature

of about 11ºC across the flow and return

when the space heating is off.

(e) Check on the A.C.B. that the appliance

reaches a suitable temperature ie above

75ºC

Summary of Contents for BMAS 150 OVR

Page 38: ...Page 38 APPENDIX APPENDIX B ...

Page 40: ...Page 40 APPENDIX D NOTES ...

Page 41: ...Page 41 NOTES ...