Ordering

Specification

Inner frame manufactured from 1.0mm galvanised

mild steel to BS 1449 Part 1, CR4 Grade ZZ. Formed

to channel shape with end flanges. The four parts of

the inner frame are rivetted together with two

stainless steel rivets 3mm diameter x 6mm long at

each of the four corners. The outer frame is

manufactured from 1.6mm galvanised mild steel

formed into 4 sections and welded to form a rigid

frame. The inner frame is secured through the flange

onto the outer frame using No6 screws.

Blades of 0.457mm stainless steel to BS 1449 Part 2,

1975 302 S16, are formed into hollow section with a

radiused leading edge and vee shaped trailing edge.

The section is spot welded together after forming at

the point of the vee, spotwelds at a pitch of 33mm.

The blade ends are closed off by stainless steel end

caps, material specification as per the blade and

have stainless steel pivot pins rivetted to them, the

pivot pins have suitable flats to engage the blade

drive pinions. The end caps are secured to the blade

by three 2.8mm diameter stainless steel rivets 6mm

long at each end.

Holes in the inner side frame to accept the blade

pivot pins are set at suitable spacings to allow blade

leading edges to interlock in the vee of the next

blade. Side seals of 0.152mm stainless steel as per

blade specification, are formed and pierced to accept

blade pivot pins, and are assembled between frame

sides and blade ends. Top and bottom seals are

manufactured in material as for side seals but are

retained on top and bottom inner frames by nibs

formed in frame inner surfaces.

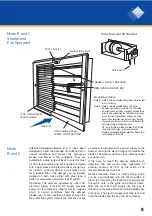

The blades are actuated by a 3mm thick x 40mm

steel rack located in the side frame, and acting on

steel pinions attached to blade pivot pins. The rack

and pinions are zinc plated and passivated, and are

contained in the side frame by a cover plate for

Modes B and C, the blades are held in the open

position via the rack, which in turn is held by a conical

ended stainless steel pin engaging in a female

keyhole aperture in the rack. The action of the rack

through the spring action is to disengage the pin, but

this is prevented by an electro-magnet. When the

electro-magnet is deenergised it allows the stainless

steel pin to move forward, thus disengaging the rack

which moves immediately to the closed position

shutting the blade pack.

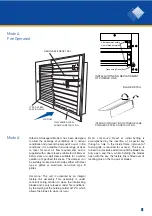

For Mode A units a 72°C Fusible link is mounted on

pivot brackets on the two opposed action blades. On

failure of said fuse link blades are allowed to move in

opposed directions, synchronised and driven by the

spring loaded rack and pinion arrangement.

Engineering

Specification

G

RILLES

:

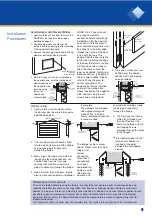

TYPE A - All steel construction with

horizontal louvres on 8.5mm

centres with a 30° downward

deflection.

TYPE B - Manufactured from

extruded aluminium with vision

proof core.

N

OTES

:

1.

MODE A type of unit provided with

a fusible link set to operate at

72°C.

2.

MODE B & C type of unit provided

with a Thermal Circuit Breaker set

to operate at 72°C.

3.

MODES B & C type of units which

are required for door mounting are

provided with electrical jump loop

to transfer wiring from door to

jamb.

4.

All units provided with 1.6mm mild

steel galvanised sleeve to suit

wall/door thickness.

F

INISH

:

Standard Finish is a PPC satin silver.

Special Finishes are PPC to any stock

BS/RAL colour.

SERIES: SMOKEGARD

Failsafe Closed-

Mode A.................................SG/A

Mode B.................................SG/B

Mode C.................................SG/C

Failsafe Open-

Mode RB.................. .........SG/RB

Mode RC................ ...........SG/RC

SIZE (mm width x Height)

GRILLE FINISH (Please Specify)

NUMBER REQUIRED

STANDARD POWER SUPPLIES:

6 Way..........................................................G6

6 Way c/w output relay................................G6R

12 Way........................................................G12

12 Way c/w/ output relay.............................G12R

REMOTE INDICATORS:

Single unit..............................................SR1

SMOKE DETECTORS:

24V DC wire ionisation...........................SD2

MASTER MONITOR:

1 - 12 unit...............................................SMM1 -12

plus per damper

UNINTERUPTABLE POWER SUPPLIES:

6 Way..........................................................UPS6

6 Way c/w output relay................................UPS6R

12 Way........................................................UPS12

12 Way c/w/ output relay.............................UPS12R

DOOR MOUNTED................D

WALL MOUNTED.................W

WALL THICKNESS (mm)

GRILLE TYPE A or B

SG/A

300 x 200

125T

A

PPC

SATIN

SILVER

(Standard

Finish)

15

W

SMOKEGARD

Door, Wall and Partition Mounting Smoke and Fire Dampers

Gilberts (Blackpool) Ltd reserve the right to alter the specification without notice. For our latest product data please visit www.gilbertsblackpool.com. The information

contained in this leaflet is correct at time of going to press

©

2013.

GILBERTS

Head Office and Works

GILBERTS (BLACKPOOL) LTD

Gilair Works, Clifton Road,

Blackpool.

Lancashire FY4 4QT.

Telephone: (01253) 766911

Fax:

(01253) 767941

e-mail:

Web:

www.gilbertsblackpool.com