Test Data

Fire Tests

Introduction

All fire tests where conducted by the WARRINGTON RESEARCH CENTRE

to BRITISH STANDARD 476 PART 20 1987.

This test describes the performance of structural elements under fire conditions,

and considering there is no standard test for this type of fire damper it was

decided to mount both a fusible link operated, and also an electro-magnet

operated fire damper in a standard 1 hour timber fire door.

Test Description

Tests were conducted in order to test both the stability and integrity of the units,

and it was felt that mounting them in a fire door would demonstrate the most

severe combined situation for which the units would likely be installed. Not only

were the fire dampers scrutinised during the test, but also the combined

situation thus demonstrating the total integrity of the installation.

Units tested were of a size 400 Wide x 400mm High which is the largest

manufactured size for this type of unit. They were installed within 54mm thick

fire doors with a suitable backing flange, and secured with mild steel bolts from

one face flange to the other through the door itself. The combined assembly was

placed vertically against one open side of a 1m

3

furnace and then securely

bolted to maintain an air seal between.

Test Results

The duration of the test was 1 hour, and only slight charring of the timber around

the damper frame was apparent after this time. At the end of the test the integrity

and stability of both the damper and door had been maintained.

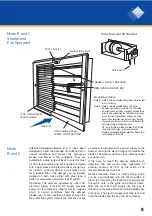

Air Flow

Test Data

Introduction

The air flow test was conducted by the Building Research and Information Association.

3

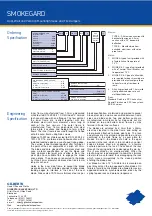

2

100

9

8

7

6

5

4

3

2

10

9

8

7

6

5

4

3

2

1.0

0.0001

0.001

0.01

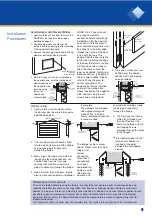

Pressure drop across unit Pa

VOLUME M

3

/

s

A

IR FLOW LEAKAGE CHARACTERISTIC OF A

300

X

200

MM

S

MOKEGARD FIRE DAMPER IN THE CLOSED POSITION

F

LOW RATE

-

PRESSURE DROP CHARACTERISTIC FOR MULTI

-

BLADE FIRE DAMPER IN OPEN POSITION

100

9

8

7

6

5

4

3

2

Pressure drop across unit Pa

10

9

8

7

6

5

4

3

2

200x100

300x100 200

x200

40

0

x100

30

0

x200

20

0

x300

40

0

x200

30

0

x300

200x

4

00

400x

3

00

300x

4

00

400x

4

00

0.01

0.1

1.0

VOLUME M

3

/

s

0.05

0.5

TEST DURATION

100

200

300

400

500

600

700

800

900

1000

0

1100

1200

TEMPERATURE - DEGREES C

S

TANDARD TIME

-

TEMPERATURE

CURVE OF

BS476 PART 20 1987

12