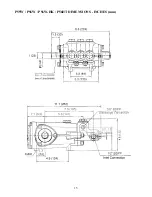

10

1. With a 22mm socket, remove

the three discharge (43) and

three inlet (41) manifold plugs.

Check o-ring (44) for wear and

replace as necessary.

P55W / P56W / P56W-HK REPAIR INSTRUCTIONS

NOTE: Always take time to lubricate all metal and nonmetal parts with a light film of oil before reassembly.

This step will ensure proper fit, at the same time protecting the pump nonmetal parts (i.e., the elastomers)

from cutting and scoring.

3. Use a small slide hammer to

remove valve seats (37) from

manifold (29). Inspect valve

plates (36) and valve seats (37)

for wear. If excessive pitting is

seen, replace the worn parts.

Check valve seat o-ring (38) for

wear and replace as necessary.

Tighten manifold plugs (41 and

43) to 50 ft.-lbs.

2. Remove the discharge spring

retainer (34), valve spring (35),

and valve plate (36).

8. Inspect and clean the manifold and pressure ring.

Reinstall the pressure ring (30) with the groved side

pointed towards the front. Insert v-sleeve (31) high

temperature seals ( 31A for P56W-HK &P56HT

pumps), support ring (32), and pressure spring (33) into

the manifold (29).

30

32

33

4. Drain the oil from the pump.

Turn the pump over to remove

the four manifold stud nuts (46)

with a 17mm wrench.

7. Turn the manifold (29) over.

Using a 15mm socket, tap out

the v-sleeves, Insert v-sleeve

(31) high temperature seals

( 31A for P56W-HK &P56HT

pumps), support rings (32), and

pressure rings (30) through

back of manifold.

5. Tap the back of the manifold

(29) with a rubber mallet to

dislodge, and slide off the

pump.

6. From the front inlet valve ports,

remove the inlet valve assembly

(34-40) and pressure springs

(33).

31

31A

(P56W-HK & P56HT)