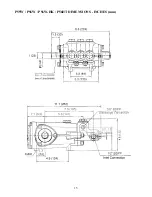

11

14. Before replacing pump mani-

fold (29), first rotate crankshaft

(18) until two outside plungers

(24A) extend evenly forward.

Next lubricate v-sleeves (50) in

the rear v-sleeve housing (48)

and slide housing over plung-

ers. Lubricate ceramic plungers

with a light film of oil. Care-

fully and evenly slide manifold

over plungers and press

manifold firmly against

crankcase (1). Replace

manifold stud bolts (45),

washers (47) and nut (46) and

tighten to 35 ft.-lbs.

11. Inspect ceramic plunger (24A)

tips for wear. If necessary,

replacement of the ceramic

plungers may be accomplished

by removing the plunger bolt

assemblies (24B and 24C) with

a 13mm wrench. Ceramic

plungers should now slide off

the stainless steel plunger base

(22). Excessive resistance to

plunger removal may be

overcome by heating the

stainless steel plunger base.

This will melt any excess loc-

tite beneath the ceramic plunger

allowing easy removal.

12. Replace copper ring (24C) onto

plunger bolt (24B). Slide

plunger bolt assembly into

ceramic plunger (24A). Apply

a light film of loc-tite to

plunger bolt threads and place

plunger assembly onto stainless

steel plunger base (22) and

tighten to 105 in.-lbs.

13. To replace plunger oil seals

(26), proceed to “Gear End

Disassembly” section below.

Otherwise, continue as de-

scribed below.

24C

9. If pitted or worn, replace inlet valve seats (36), valve

plates (37), springs (35) and spring retainers (34).

Re-insert items 34-38 into valve adapter (39). Install

valve assembly (34-40) into manifold (29). Reinstall

manifold plugs (43) and torque plugs to 50 ft.-lbs.

36

37

35

34

10.The rear v-sleeve housing

(48) may be removed by

prying evenly outward

with a flat screwdriver.

After slipping housing

over ceramic plunger

(24A), inspect seals (50)

and o-ring (49) and

replace as necessary. If the

crankcase is to be disas-

sembled, the housing

should not be replaced

until later.

48

49

50