Reviews:

No comments

Related manuals for SRL 6-60

891

Brand: X-Rite Pages: 80

Vigilant ELM Series

Brand: Eagle Eye Power Solutions Pages: 9

DG30

Brand: Kawai Pages: 19

6425

Brand: Calculated Industries Pages: 64

EXTREME DUTY TPMS

Brand: Valor Pages: 2

825-505

Brand: ETI Pages: 2

CMP-400

Brand: Sonel Pages: 84

SL-510

Brand: Apogee Pages: 18

PF3S Series

Brand: Suaoki Pages: 79

Mini HD Recorder

Brand: Green Feathers Pages: 8

SC40FR

Brand: Smartwares Pages: 2

DUSTHUNTER SB30

Brand: SICK Pages: 72

Exeter 770

Brand: Rodgers Pages: 54

ChronoMaster

Brand: Witschi Pages: 50

HI 98180

Brand: Hanna Instruments Pages: 72

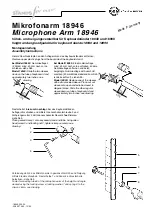

18946

Brand: K&M Pages: 2

OPTISWIRL 2100

Brand: KROHNE Pages: 100

HVFO108

Brand: Teledyne Lecroy Pages: 48