3

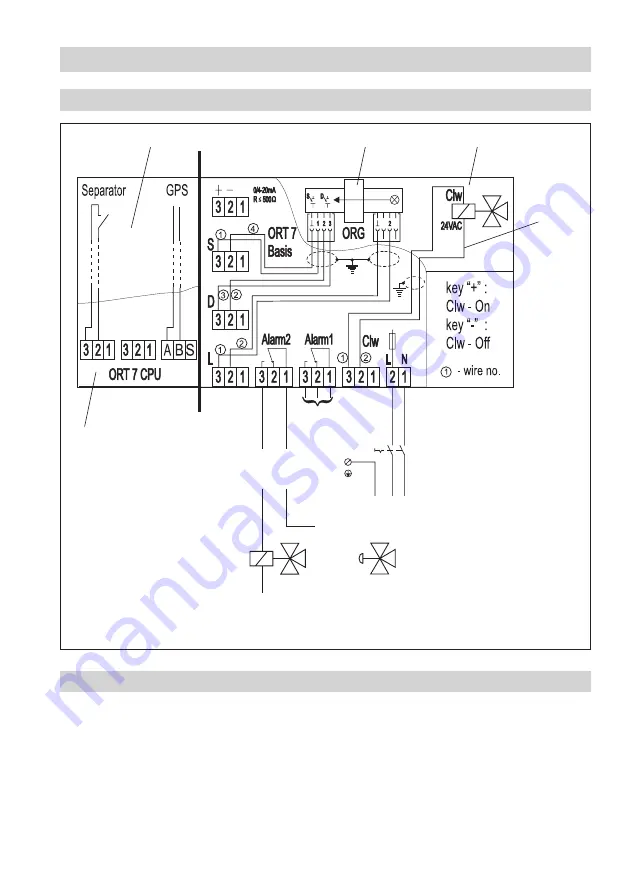

Electrical Connection

- continued -

Wiring diagram OR 52-7

Fig. 4

Drawn position of contacts: Alarm 1 and 2, separator OFF and voltage failure

Notice

Fig. 4

shows an example where the water will be run back to the ship’s bilge in the event of an alarm

(oil content > 5 ppm) or auxiliary power failure.

With different limit settings alarm contact can, for instance, be used for the first alarm and alarm

contact 2 for the main alarm.

For bilge water monitoring a pneumatic three-way valve can be controlled by the alarm contact 2 via a

solenoid valve. If the turbidity of the effluent is too high (alarm caused by ingress of oil or dirt particles

introduced into the system during start-up) the three-way valve will divert the contaminated water to

the bilge tank. The separation continues until the oil content falls below 5 ppm and the cleaned water

can be discharged overboard.

External wiring

Measuring sensor

Disconnecting

switch

External

wiring

Purging valve

to first alarm

Attached in cover

Solenoid valve

Three-way valve

Earthing screw

in housing

PE L N

N

L

Summary of Contents for OR 52-7

Page 15: ...15 Functional Elements Measuring sensor ORG 12 Measuring transducer ORT 7 Fig 6 p n m o 9 e q ...

Page 32: ...32 Annex Type approval certificate ...

Page 33: ...33 Annex continued Type approval certificate continued ...

Page 34: ...34 Annex continued Type approval certificate continued ...

Page 35: ...35 Annex continued Type approval certificate continued ...

Page 36: ...36 Annex continued EC Prototype Test Certificate module B ...

Page 37: ...37 Annex continued EC Prototype Test Certificate module B continued ...

Page 38: ...38 Annex continued EC Type Examination Module B Certificate ...

Page 39: ...39 Annex continued EC Type Examination Module B Certificate continued ...

Page 40: ...40 Annex continued Declaration of Conformity ...

Page 41: ...41 For your notes ...

Page 42: ...42 For your notes ...

Page 43: ...43 For your notes ...