1)

Optional accessories / Option depending on model

Original instruction

19

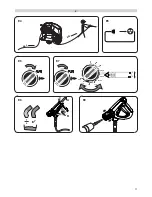

B6. Antiscale adjustment

1. Open cabinet (A).

Measure the water hardness or ask your water supply company.

2. Adjustment knob (B) setting

according to rated water flow

mg/l

Grains

°dH

°e

°f

ppm Ca

Description

9-15

L/min

16-20

L/min

21-26

L/min

27-33

L/min

.0-17

0-1

0-7

0-8,8

0-12,5

0-50

Soft

0

0

0

0

17-60

1,1-3,5

Slightly Hard

0,5

1

2

2

60-128

3,6-7,5

7-14

8,8-17,5

12,5-25,1

51-150

Moderately Hard

1

1,5

2,5

3

128-180

7,6-10,5

14-21

17,5-26,3 25,1-37,6

151-300

Hard

1,5

2

3

3,5

>180

>10,5

>21

>26,3

>37,6

>300

Very Hard

2

3

3,5

4

Indications on Display

Indication lights

Display Cause

Remedy

Constant

0024

- The appliance is ready for operation.

- At power on to cold mode, hour coun-

ter is shown for a few seconds.

Flashing

- Water tap closed or water shortage.

- Detergent tank empty.

- Pressure regulation on the safety con-

trol blocks or the VarioPress

1)

lance is

set to low water volume.

- Machine scaled.

- Check water supply.

- Refill detergent or set Detergent knop to “0“.

- Change setting on safety control block / Vario-

Press to allow full water flow.

- Contact dealer/service dpt.

Flashing

FLO

- Machine has run for more than 120s

without propper water supply. Machine

shuts down to avoid pump over-

heating.

- Restart machine, if fault continues

- Contact dealer/service dpt.

Constant

FUE

- Low fuel level.

- Cold water operation possible.

- Check fuel level and refill, error reset after 5

sec.

Constant

- Low Nilfisk AntiStone level

1)

.

- Machine is still operational.

- Check Nilfisk AntiStone level and refill.

Constant

Constant

- Service interval has expired.

- Machine is still operational.

- Contact dealer/service dpt.

Constant

Flashing

- Service interval due in 20 hours.

- Machine is still operational.

- Contact dealer/service dpt.

Constant

HOS

- Boiler overheated. Exhaust sensor

(EXT-H) has cut off fuel supply.

- Machine scaled.

- Boiler not serviced.

- Cold water operation is possible.

- Contact dealer/service dpt.

Constant

Constant

LHE

- Flame sensor (B7) is sooted.

- Ignition or fuel system failure.

- Cold water operation is possible.

- Clean flame sensor (B7).

- Contact dealer/service dpt.

Flashing

Flashing

LHL

- Boiler is over sootet and needs

service.

- Boiler is filled with diesel.

- Contact dealer/service dpt.

Constant

Constant

HOP

- Motor is overheated.

- Turn main switch to “OFF” position - let the

machine cool down.

- Remove/disconnect extension cable.

- Possible phase failure.

- Have electrical connection checked.

- Contact dealer/service dpt.

Constant

Flashing

Flashing

SEC

SEO

- Temperature sensor shorted.

- Temperature sensor is disconnected.

- Cold water operation is possible.

- Contact dealer/service dpt.

Constant

Constant

FLF

- Flow sensor fault.

- Contact dealer/service dpt.

Constant

POL

- Low pump oil.

- MPU is leaking oil.

-Check oil lever and refill.

- Contact dealer/service dpt.

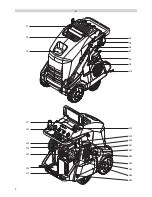

Summary of Contents for MH 4M

Page 1: ...107144382 E 04 2017 MH 4M MH 5M MH 6P MH 7P Operating instructions ...

Page 8: ...8 B B5 B4 a A B4 b B B B A B6 ...

Page 9: ...9 B C B7 B9 B8 C1 a C1 b C B A C1 c ...

Page 10: ...10 C D E C2 D1 10 10 0 C 32 F 40 C 104 F D3 E1 D4 E2 D2 A E3 B C A C D5 ...

Page 14: ...14 F G F4 G1 C B C G2 F7 F5 F6 0 C 32 F ...

Page 15: ...15 H H2 H4 H3 H1 a H1 b A A A A B B B B C ...

Page 16: ...16 H H5 H6 A B C MIN C ...