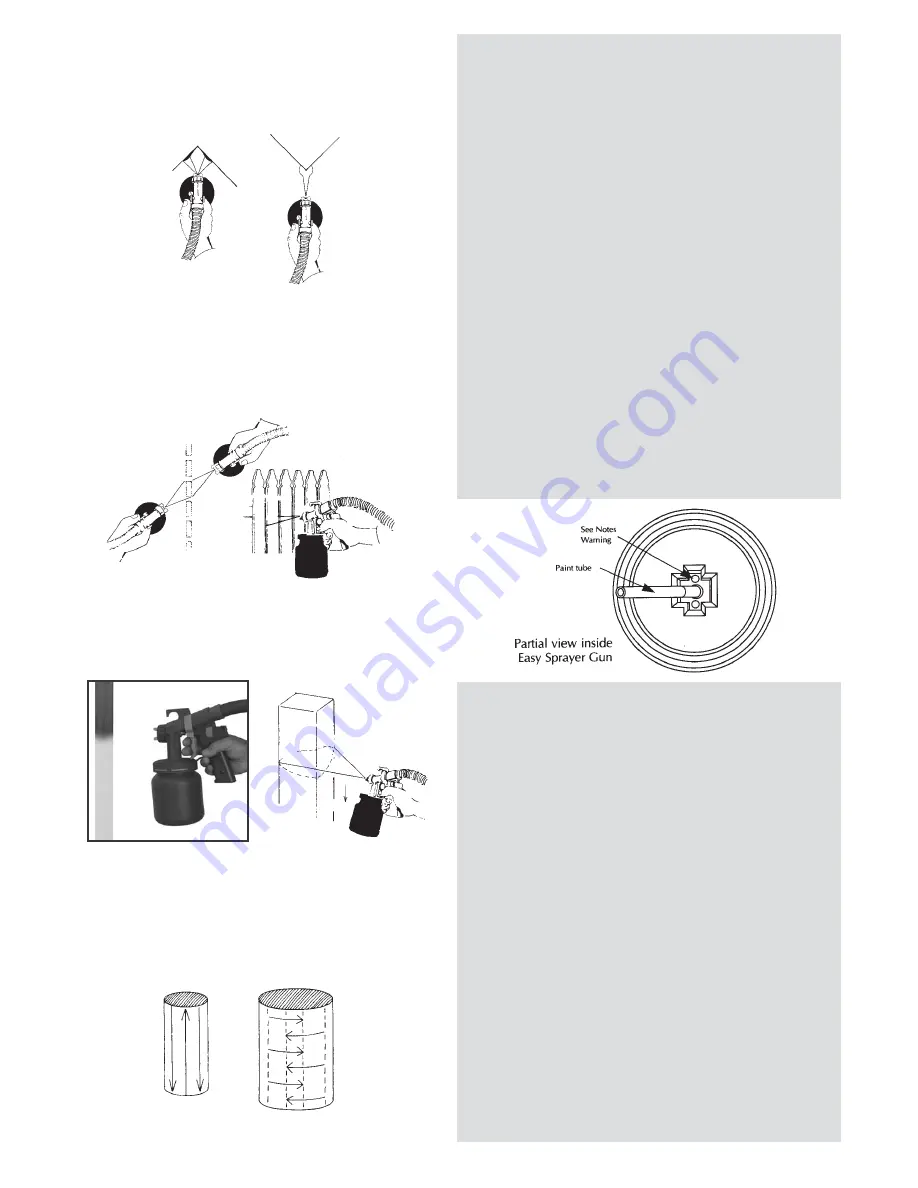

Spraying Corners

Holding the gun pointed at the corner, spray both

surfaces at once. This reduces overspray falling on

adjacent surfaces.

Spraying picket fences and open work

Place a large piece of cardboard behind the fence to

catch any spray passing through. Spray each picket at an

angle to cover the front and one edge, then from the

other side spray the back plus the other edge.

Spraying slender work

Screw in the paint control to achieve the narrow spray

pattern and spray two adjacent surfaces at once.

Spraying round work

For cylinders up to about a metre high and wide, spray up

and down using a horizontal spray pattern. For larger

cylinders spay around the cylinder in sections using a

vertical spray pattern. (See "Spraying long work").

CARE OF EQUIPMENT

- Paint tube should always be pressed firmly into place.

- Ensure that lid washer is in place when replacing paint

container. Then twist paint container firmly into main gun body.

- Do not force paint adjustment screw. Forced adjustment is not

necessary and may damage the gun voiding the warranty.

Before attaching or detaching the paint container ensure that the

air supply and power are turned off. Keep the threads on the container

and spray gun clean to allow an airtight seal when the container is

screwed into place.

IMPORTANT:

Clean the gun immediately after use as follows:

Turn off the air supply, remove and empty the paint container.

Hold the gun with paint tube over a paint container and

squeeze the trigger, this will allow paint in paint tube to run out.

Use the appropriate solvent for the paint and a rag or brush, clean the

paint tube, inside surfaces of the lid, the paint container, the air cap and

the nozzle. Remove the retaining nut being careful not to damage any

of the holes in the air cap or nozzle. If holes have become clogged,

never use a wire or other metallic instrument to clear them: they are

drilled to precision tolerance and any enlargement or distortion by the

abrasive action of an instrument will permanently affect the spray

pattern and void the warranty.

Replace the air cap and retaining unit. Place a small quantity of

solvent in the container, and spray through until clean. Wipe all

excess paint from the gun and wipe over the blower unit.

A further requirement may be to clean the hole situated inside the

gun (see below).

This hole, through prolonged periods of intermittent use may clog

up with dry paint making spraying very difficult. Ideally use solvent

or long piece of timber dowel, being careful not to damage or enlarge

the hole.

Note:

Periodic inspection for efficient and problem free work is

required in this area.

Before putting the spray gun away, place a drop of oil on the

shank of the needle between the trigger and the front of the gun.

Inspect the lid washer to ensure that it is in place and undamaged.

Replace, if it becomes perished or distorted.

The spraygun needle assembly must always be clean. Paint allowed to

dry will block the flow of paint and produce a poor or no spray pattern

at all. To Clean the needle assembly remove the air cap and screw, the

fluid tip is now visable (brass tapered nut with central hole), using a

18mm ring spanner or socket unscrew anticlockwise, the needle tip

and fluid tip can now be throughly cleaned.

Note:

Paint left to dry in the spraygun is not covered under warranty.

This is the responsibility of the operator.

CAUTION

Always use a respirator when spraying toxic paint

If in doubt contact the paint manufacturer to ascertain if a respirator is required.

DON'T

1.

Dismantle the rest of the gun more than is necessary.

This only causes excessive wear on threads and other parts.

2.

Immerse the whole gun in solvent or thinners. This removes oil,

causes packing glands to dry out and the lid washer as well.

3.

Drop the gun and expect it to be unaffected. If you do have such an

accident, carefully check the spray pattern to see that the

nozzle assembly had not been damaged.

The power unit is sealed at the factory. for safety reasons, electrical repairs should

only be performed by qualified technicians. Defective units should be returned to

GEPRO Approved Repair Agent.

6