10

ECO-Y INSTALLATION MANUAL

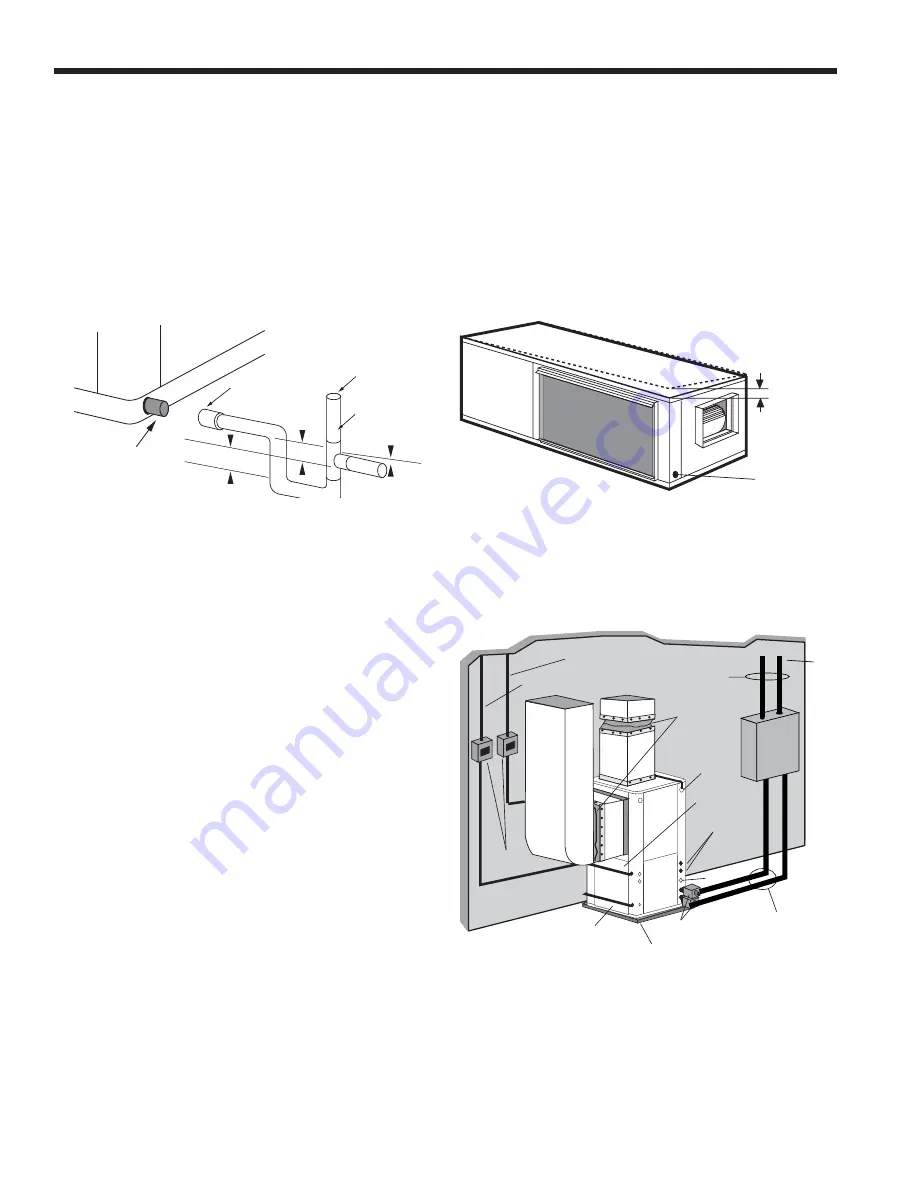

1/2'' Pitch

Drain

Unit Pitch for Drain

Horizontal Drain Connection (Composite Drain Pan)

Condensate Drain

On vertical units, the internal condensate drain assembly consists

of a drain tube which is connected to the drain pan, a 3/4 in. PVC

female adapter and a flexible connecting hose. The female adapter

may exit either the front or the side of the cabinet. The adapter

should be glued to the field-installed PVC condensate piping.

On vertical units, a condensate hose is inside all cabinets as a

trapping loop; therefore, an external trap is not necessary.

On horizontal units, a PVC stub is provided for condensate drain

piping connection. An external trap is required (see below). If a

vent is necessary, an open stand pipe may be applied to a tee in

the field-installed condensate piping.

1.5"

1.5"

3/4” PVC tube stub

3/4" PVC

Coupling

Vent (if needed)

3/4" PVC

1/8" per foot

NOTE:

For closed loop systems with antifreeze protection, set

SW1-2 to the “loop” position.

Once piping is completed between the unit, pumps and the ground

loop, final purging and charging of the loop is required. A flush

cart (or a 1.5 HP pump minimum) is needed to achieve adequate

flow velocity in the loop to purge air and dirt particles from the

loop itself. Antifreeze solution is used in most areas to prevent

freezing. Flush the system adequately to remove as much air as

possible then pressurize the loop to a static pressure of 40-50

PSI (summer) or 50-75 PSI (winter). This is normally adequate

for good system operation. Loop static pressure will fluctuate with

the seasons. Pressures will be higher in the winter months than

during the cooling season. This fluctuation is normal and should be

considered when initially charging the system.

After pressurization, be sure to turn the venting (burping) screw in

the center of the pump two (2) turns open (water will drip out), wait

until all air is purged from the pump, then tighten the plug. Ensure

that the loop pumps provide adequate flow through the unit(s)

by checking the pressure drop across the heat exchanger and

comparing it to the unit capacity data in the specification catalog.

2.5 to 3 GPM of flow per ton of cooling capacity is recommended in

earth loop applications.

Closed Loop Ground Source Systems

Closed Loop Ground Source Application

Flexible Duct

Collar

Vibration Absorbing Pad

P/T Plugs

Drain

Hot Water Generator

Connections

Auxiliary

Heater

Knockout

Low

Voltage to

Thermostat

Unit Supply

Auxiliary Heat

Supply

Insulated piping

or hose kit

Disconnects

(If Applicable)

Unit Power

P/T

TO

LOOP

GeoLin

k

®

Flow

Center

GeoLink

®

Polyethylene w/

Armaflex

®

Insulation

NOTE:

Additional information can be found in Flow Center

installation manual and Flush Cart manual.