Page 9/55

© Geobrugg AG, CH-8590 Romanshorn, Switzerland

RXE-1000 / 17

2

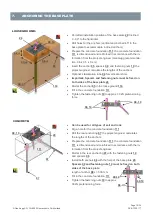

INSTALLATION TOOLS

M

A

R

KI

NG

•

30

– 50 m measuring tape

•

Measure stick

•

5 red and white ranging poles

•

Inclinometer

•

Spray can

•

Wooden peg or iron peg (min. 3x for each field)

•

Hammer/mallet

•

Manual

INSTA

L

L

A

T

IO

N

•

Open-ended or ring wrench

•

Socket wrench set with ratchet

•

Torque wrench, range 25

– 400 Nm (see tightening torque required for wire rope clips and base

plate fastening nuts)

•

Open-ended wrench for base plate fastening nuts

•

Felco C16 or C112 wire rope cutter or similar; 12 mm cutting capacity

•

Cutting-Off wheel or hammer wire cutter; 28 mm cutting capacity

•

pincers, flat-nose pliers

•

2 mm galvanized wire strands or wire

•

Angle spirit level

•

Roll of adhesive tape

•

Rope clamp, small 8

– 16 mm / large 14 – 26 mm (min. 2x)

•

At least 2 tension belts

•

Cable winch hoist, e.g. LUG-ALL

®

•

Chain hoist or HABEGGER wire rope hoist, min. 1.5 t (15 kN)

•

Auxiliary ropes

Summary of Contents for RXE-1000

Page 2: ...Page 2 55 Geobrugg AG CH 8590 Romanshorn Switzerland RXE 1000 17 ...

Page 3: ...Page 3 55 Geobrugg AG CH 8590 Romanshorn Switzerland RXE 1000 17 ...

Page 52: ...Page 52 55 Geobrugg Gruppe CH 8590 Romanshorn Switzerland RXE 1000 17 ...

Page 53: ...Page 53 55 Geobrugg AG CH 8590 Romanshorn Switzerland RXE 1000 17 ...

Page 54: ...Page 54 55 Geobrugg Gruppe CH 8590 Romanshorn Switzerland RXE 1000 17 ...