Section 3 • Scheduled Maintenance Procedures

3 - 10

GR-20J • GR-26J

Part No. 227656

September 2016

Checklist B Procedures

B-1

Inspect the Battery

Genie specifications require that this procedure be

performed every 250 hours or quarterly, whichever

comes first.

Proper battery condition is essential to good

machine performance and operational safety.

Improper fluid levels or damaged cables and

connections can result in component damage and

hazardous conditions.

Electrocution/burn hazard. Contact

with electrically charged circuits

could result in death or serious

injury. Remove all rings, watches

and other jewelry.

Bodily injury hazard. Batteries

contain acid. Avoid spilling or

contacting battery acid. Neutralize

battery acid spills with baking soda

and water.

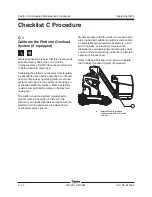

1 Open the turntable covers of the machine.

2 Confirm that the battery cable connections are

tight and free of corrosion.

Note: Adding terminal protectors and a corrosion

preventative sealant will help eliminate corrosion

on the battery terminals and cables.

3 Locate the bolts between the battery pack and

the counterweight. Confirm that the head of

each bolt is firmly in contact with the battery

pack so that the battery pack does not move.

a

battery B9

b

fuse 250A F9

c

emergency stop button P1

d

motor controller U6

e

battery charger indicator G7

f

battery charger U9

4 Put on protective clothing and eye wear.

5 Remove the battery vent caps and check the

battery acid level. If needed, replenish with

distilled water to

1

/

8

inch / 3 mm below the

bottom of the battery fill tube. Do not overfill.

6 Install the vent caps and neutralize any

electrolyte that may have spilled.

U9

Battery Charger

F9

250A Fuse

U6

Motor Controller

B9

12-2V

a

P1

G7

b

c

d

f

e