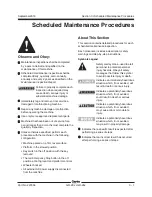

Section 3 • Scheduled Maintenance Procedures

Part No. 227656

GR-20J • GR-26J

3 - 5

September 2016

Maintenance Inspection Report

Checklist B

Y N R

B-1

Inspect the battery

B-2

Electrical wiring

B-3

Tires and wheels

B-4

Emergency stop

B-5

Horn

B-6

Key switch

B-7

Drive brakes

B-8

Drive speed - stowed

B-9

Drive speed - raised

B-10 Flashing beacon

(if equipped)

B-11 Motion alarm

B-12 Hydraulic oil analysis

B-13 Breather cap

B-14 Rear axle free-wheeling

B-15 Lateral offset of

the mast

B-16 Mast wear pads

Checklist C

Y N R

C-1 Calibrate platform

overload (if equipped)

C-2 Breather cap - models

with optional oil

Checklist D

Y N R

D-1 Tank return filter

Checklist E

Y N R

E-1

Hydraulic oil

Checklist A

Y N R

A-1

Inspect the manuals

and decals

A-2

Pre-operation

inspection

A-3

Function tests

Perform after 40 hours:

A-4

30 day service

Perform every 100 hours:

A-5

Hydraulic suction

strainer

Instructions

• Make copies of this report to use for

each inspection.

• Select the appropriate checklist(s) for

the type of inspection to be

performed.

Daily or 8 hours

Inspection:

A

Quarterly or 250 hours

Inspection:

A+B

Semi-annually or

500 hours

Inspection:

A+B+C

Annually or

1000 hours

Inspection:

A+B+C+D

Two year or

2000 hours

Inspection:

A+B+C+D+E

• Place a check in the appropriate box

after each inspection procedure is

completed.

• Use the step-by-step procedures in

this section to learn how to perform

these inspections.

• If any inspection receives an “N”, tag

and remove the machine from service,

repair and re-inspect it. After repair,

place a check in the “R” box.

Legend

Y = yes, acceptable

N = no, remove from service

R = repaired

Model

Serial number

Date

Hour meter

Machine owner

Inspected by (print)

Inspector signature

Inspector title

Inspector company

Comments