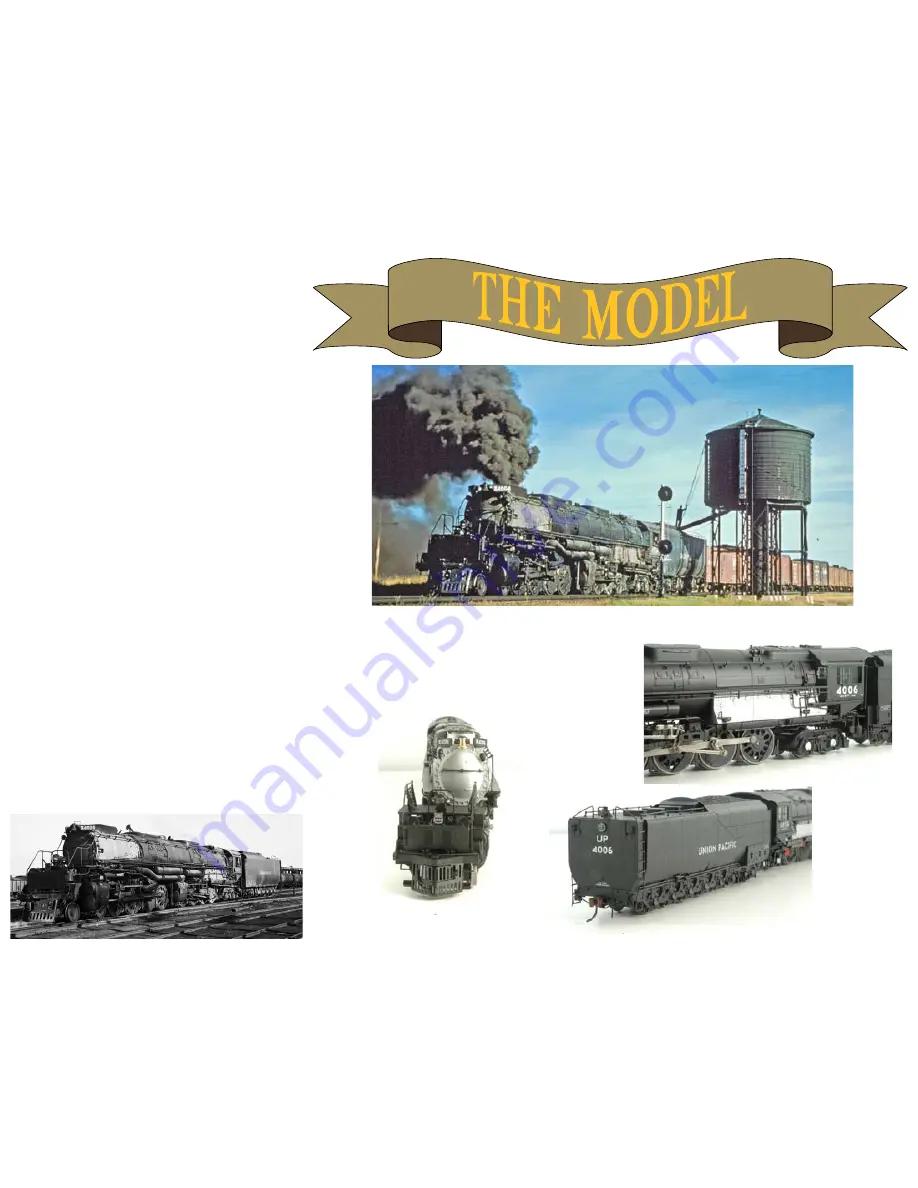

G9150 BIG BOY UNDECORATED W/O DEFLECTORS

G9151 BIG BOY UNDECORATED W/ DEFLECTORS

G9152 BIG BOY #4005

G9153 BIG BOY #4006

G9154 BIG BOY #4019 WITH DEFLECTORS

G9155 BIG BOY #4024

Ogden to Pocatello, Idaho and from Granger, Wyoming to

McCammon, Idaho, but they were not used on those lines.

Because Cheyenne was their home shop for heavy work, the

Big Boys regularly ran from Ogden to Cheyenne for shop-

ping. When released from the shop, it was customary to

use the Big Boy as a helper for Sherman Hill for a few runs

before releasing it back to the freight pool. Before long, the

run from Ogden to Cheyenne was the normal Big Boy operat-

ing area. Each Big Boy ran about 7,000 miles each month

throughout their careers. Producing about 6,000 horsepower,

the Big Boys were very well suited to hustling hot Pacific Fruit

Express trains over the grades of Wyoming.

Big Boys had been cleared to run the LA&SL to Los

Angeles from the beginning with some speed restrictions

on the tighter curves found in several areas. .None ran into

Nevada or California, but during World War Two, traffic on

the LA&SL route to Southern California was near the line’s

peak capacity. Several Big Boys operated for a while from

Salt Lake City to Milford, Utah to see if their power could ease

the traffic crunch. Since the LA&SL used oil instead of coal,

a clamshell coal loader was used at Lynndyl, Utah to supply

coal to the Big Boys. The biggest problem encountered was

the lack of water and very poor quality of the water found in

the desert.

Another experiment was the conversion of number 4005

to an oil burner just after the end of World War Two. The

experiment was not a success as only one burner was installed

and it heated just one spot of the crown sheet so much that the

crown sheet leaked considerable amounts of water into the

firebox. After a short period of testing, the 4005 was convert-

ed back to coal. Without dieselization, it is probable that more

Big Boys would have been acquired including oil burners for

the LA&SL.

Despite the influx of diesels following World War Two,

the Big Boys and Challengers remained the prime power on

the Overland Route from Ogden to Cheyenne. Helpers were

used on Sherman Hill including double-headed Big Boys.

They also saw service as helpers, leading gas turbines and

diesels over Sherman Hill. They remained active on through

the 1950s, not being retired until the early 1960s.

Jack Pfeifer Collection

Dave Martindell photo,

Clayton Tinkham collection

UNION PACIFIC