ENCLOSED EDGE SHAPING

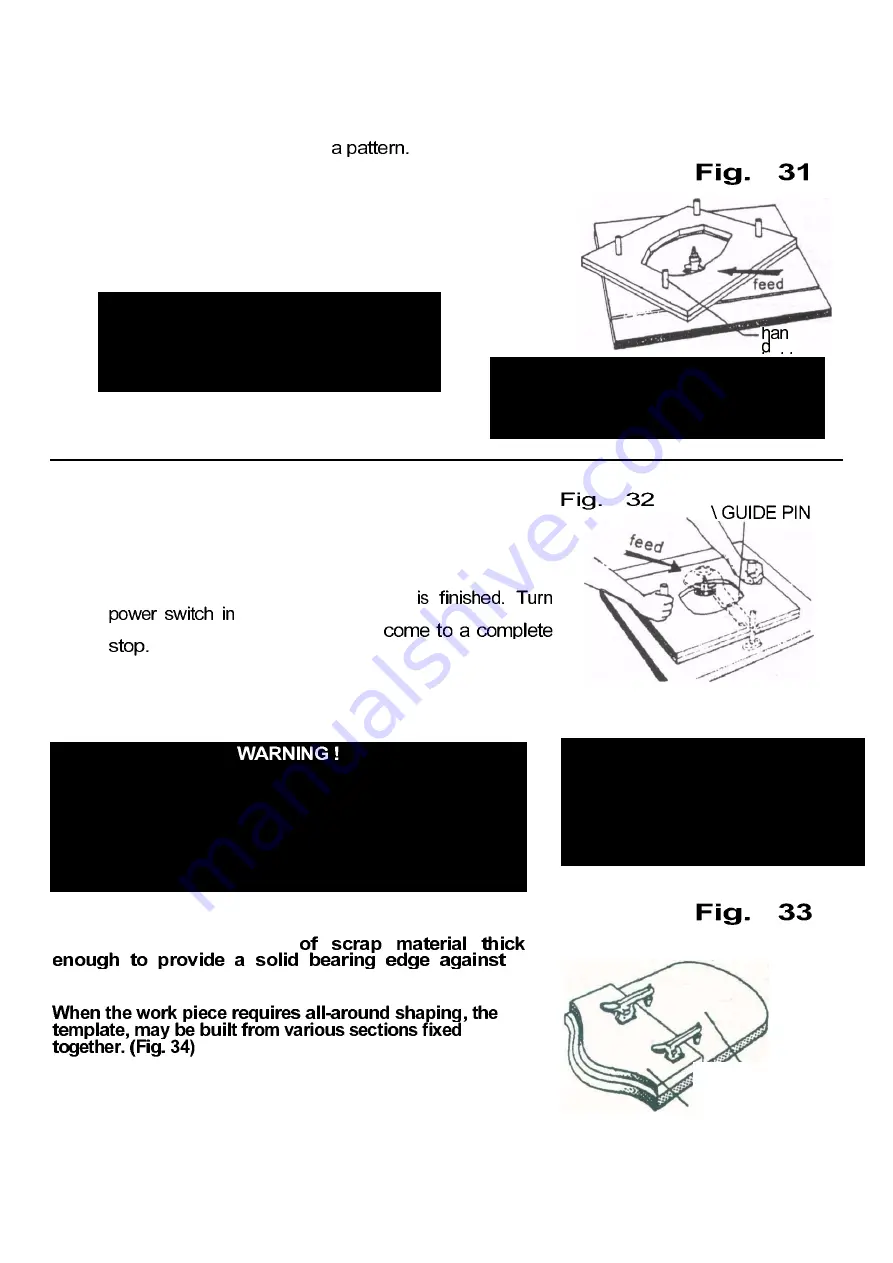

Inside edge work piece are shaped the same way as

outside edges (Fig.31). When the whole edge needs to be

shaped, the operator must use

The work piece must be placed on table before starting the

motor. The operator must shape the whole work piece by

feeding into the cutters.

WARNING !

NEVER ATTEMPT TO PERFORM THIS

PROCEDURE WITHOUT A

RING GUARD OR A SIMILAR SAFETY

DEVICE OVER

CUTTERHEAD !

ATTENTION !

OPERATION MUST BE AWARE AT ALL

TIMES OF THE FEED DIRECTION !

OPERATION MUST NOT BE LEFT

UNATTENDED!

1. Use a firm grip to ease the edge into the cutters until

stopped by the collar (Fig. 32).

2. Keep pushing straight while turning and feeding the

work piece, continue until the cut

the off position and remove the work

piece only once the cutters have

NEVER PERFORM ENCLOSED EDGE SHAPING WHEN

THERE IS LESS THAN 12" OF WOOD MATERIAL ALL

AROUND THEOPENING ! THE ONLY TIME THIS CAN BE

DONE IS IF THE WORK PIECE IS ATTACHED TO A

LARGER WOOD BASE!

TEMPLATES

A template serves as guide for the cutter. The

template must be made

a

collar, recommended size 3/4". (Fig. 33)

MULTI-PIECED TEMPLATES

workplace

template

ATTENTION !

NEVER PERFORM ENCLOSED

HAPING WHEN WORK PIECE

OPENING IS MALLER THAN TWICE

THE DIAMETER IN ANY

DIRECTION

Summary of Contents for 40-350

Page 17: ...BASE...