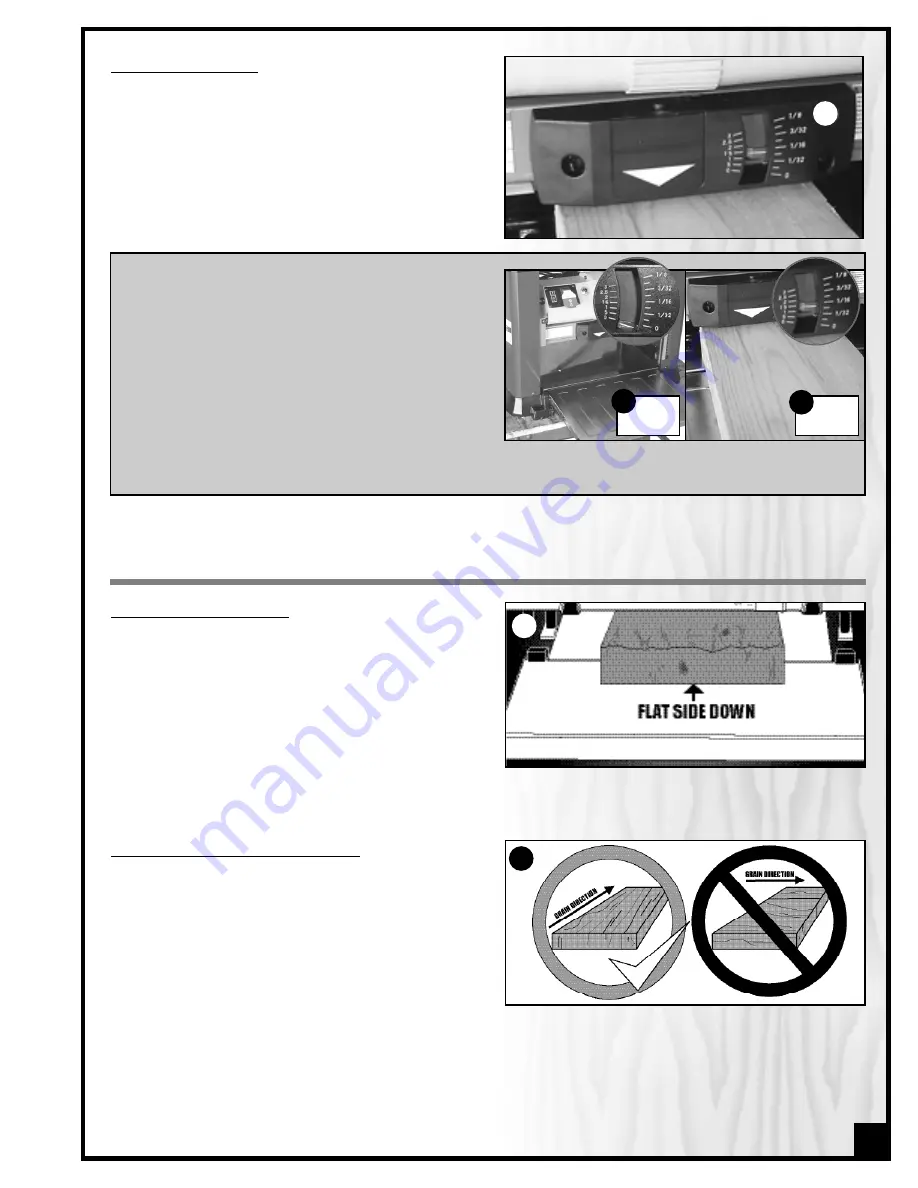

DEPTH OF CUT INDICATOR

The depth of cut indicator,

A

, will indicate how much

material the cutterhead is set to remove from the work-

piece for a given pass.

The pointer will read zero until the workpiece engages the

front of the cutterhead. Place the workpiece under the

front of the cutterhead and turn the height adjustment

handle clockwise until the cutterhead makes contact

with the workpiece & until the depth of cut indicator

shows the reading that matches the desired cut.

Failure to follow these recommendations will lead to

premature blade wear and may cause premature

motor failure.

It is recommended that for both hard and soft wood:

For stock up to 6” in width, never remove more that 1/8”

per pass,

A

.

For stock of 6”-13” in width, never remove more than

1/16” per pass,

B

.

Removing less material per pass and taking multiple

passes is always preferred to more aggressive planing.

Advantages include longer blade life, better finish quality (resulting in less time sanding later) and less likelihood

of removing too much material causing the workpiece to be too thin for its intended use.

1/8”

or less

11

A

A

OPERATING INSTRUCTIONS

BASIC PRINCIPLES OF PLANING

This thickness planer is designed to remove material from

the top face of a board in order to bring the board (or a

series of boards) down to a specific desired thickness.

To obtain even, uniform thickness across the length of a

board, the stock being planed must have one face that

has already been machined perfectly flat (usually on a

jointer) and the stock should be fed with this flat face

against the table,

A

.

If it is not possible to machine one face perfectly flat before planing, take shallow passes all on the same face of

the board until this face has been machined level. Then the board should be flipped over and the leveled face

should be fed face down against the table to allow you to dimension the board to final thickness.

SELECTING BOARDS SUITABLE FOR PLANING

This planer is not intended (and should not be used) to

plane any material other than solid wood.

The workpiece should always be fed through the planer in

the general direction of the grain in the wood,

B

.

Before being fed through the planer all lumber should be

inspected for debris and foreign objects such as staples

or nails. Foreign objects stuck to, or embedded in your

workpiece can be ejected from the machine at high

speed and cause serious injury or damage cutter knives. Make sure to remove all such foreign objects from the

wood before running it through the planer.

Select lumber carefully and avoid workpieces with loose or protruding knots. Workpieces that are twisted, severely

deformed or warped should also be avoided. Warped, twisted, damaged or fragile stock runs an increased risk of

jamming in or damaging the machine or cutters. There is also a much greater risk of injury to the operator or

bystanders from kickback, where the workpiece is forcefully or violently ejected from the machine due to a jam,

whenever working with such damaged or warped wood.

B

A

1/16”

or less

B