CONTROLS

62

Accessories

Auxiliary Hydraulic Lines

WARNING

�

Oil may spray out if caps or filters are

removed or pipes disconnected before

releasing the pressure in the hydraulic

system.

• When

removing

plugs

or

disconnecting hoses, release the

internal pressure before removing.

�

Hydraulic fluid, tubes, fittings and quick

couplers can get hot when running

machine and attachments.

Be careful when connecting and

disconnecting quick couplers.

These lines deliver the hydraulic oil necessary

for operating other attachments.

�

Auxiliary hydraulic flow rate and rated

pressure:

Flow Rate ...............

CTL55: 57 L/min (15.1 US gpm)

CTL65: 70 L/min (18.4 US gpm)

CTL75: 75 L/min (19.8 US gpm)

CTL85: 89 L/min (23.4 US gpm)

Rated Pressure ........ 20.6 MPa (2987 psi)

Quick-Couplers

Connecting: Remove dirt or debris from

the surface of both the male and female

couplers, and from the outside diameter of

the male coupler. Visually check the couplers

for corrosion, cracks, damage or excessive

wear. If any of these conditions exist, the

coupler(s) must be replaced.

Install the male coupler into the female

coupler. Full connection is made when the

ball-release sleeve slides forward on the

female coupler.

Disconnecting: Hold the male coupler.

Retract the sleeve on the female coupler

until the couplers disconnect.

Releasing Residual Pressure

Connecting: Push the quick-couplers tightly

together and hold for five seconds; the

pressure is automatically released as the

couplers are installed.

Disconnecting: Push the quick-couplers

tightly together and hold for five seconds;

then retract the sleeve until the couplers

disconnect.

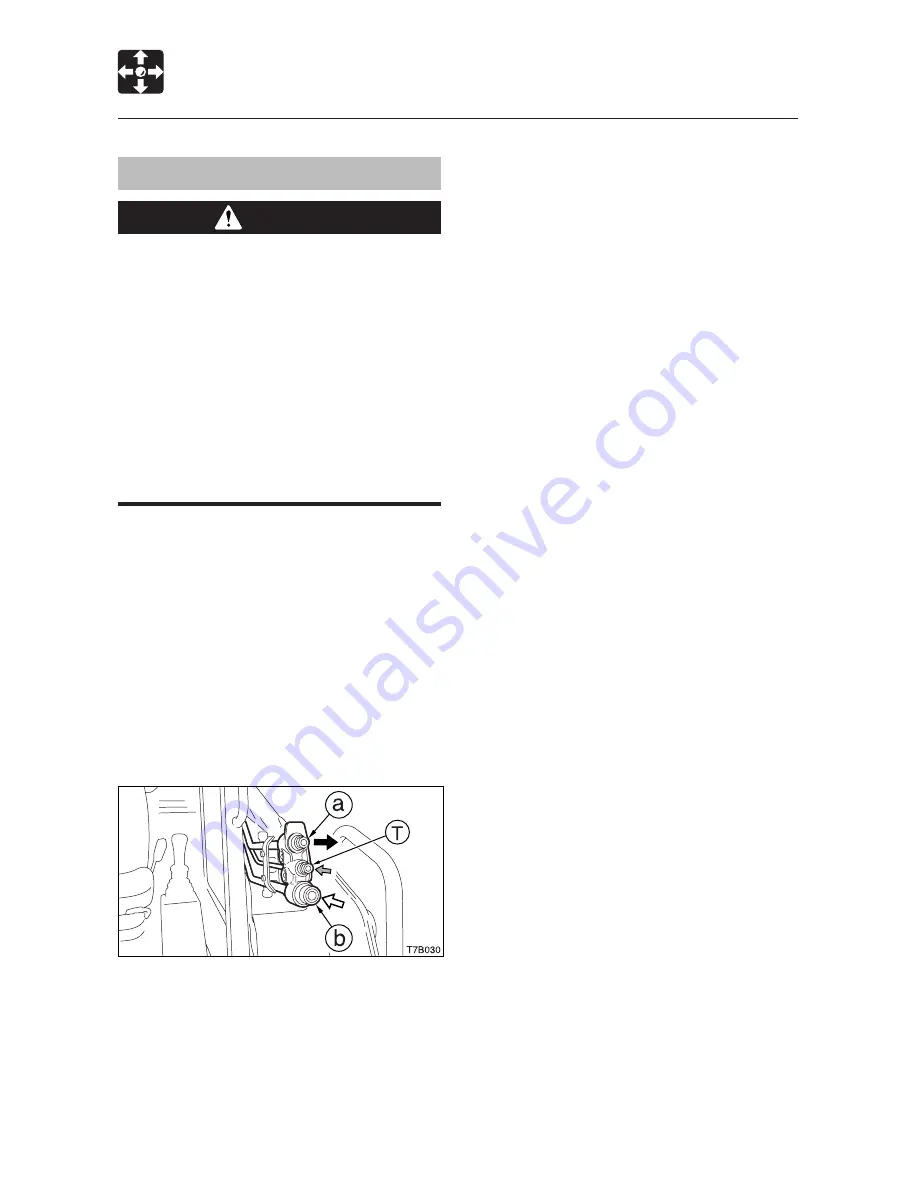

Connecting the Hydraulic Circuits

To connect attachment hydraulic lines, use

the following procedures:

1. Connect the attachment hydraulic lines to

ports (a) and (b).

When fitted with a hydraulic breaker:

a. Connect the return circuit to port (b)

and the supply circuit to port (a).

b. Turn on the flow selector switch.

Refer to page 56 “Flow Selector

Switch.”

Some attachments may have a case

drain, which needs to be the connected

to the small port (T).

2. When connecting is complete, purge air

from the hydraulic lines.

a. Start and run the engine at low idle with

no load for 10 minutes.

b. With the engine running at low idle,

operate the auxiliary hydraulics switch

repeatedly (approx. 10 times) to purge

air from the hydraulic lines.

c. Stop the engine and wait for more than

5 minutes until bubbles escape from

the hydraulic oil in the tank.

Summary of Contents for CTL55

Page 1: ...CTL55 CTL65 CTL75 CTL85 Compact Track Loader OPERATOR S MANUAL Revision E 09 10...

Page 6: ...4...

Page 8: ...6...

Page 38: ...SAFETY 36 Safety Signs Decals...

Page 39: ...37 SAFETY Safety Signs Decals...

Page 40: ...SAFETY 38 Safety Signs Decals...

Page 66: ...64 MEMO...

Page 67: ...65 MEMO...

Page 68: ...66 MEMO...

Page 69: ...67 MEMO...

Page 70: ...68...

Page 114: ...MAINTENANCE 112 Maintenance Log Date Hours Service Procedure...

Page 115: ...113 MAINTENANCE Maintenance Log Date Hours Service Procedure...

Page 123: ...121 MEMO...

Page 129: ...127 MEMO...

Page 156: ...154...

Page 170: ...168...

Page 171: ...169 Main Speci cations 170 Machine Dimensions 174 Operating Range 176 SPECIFICATIONS...

Page 176: ...SPECIFICATIONS 174 Machine Dimensions...

Page 178: ...SPECIFICATIONS 176 Operating Range T7K0021 F H C A D B G E...

Page 180: ...178...

Page 181: ...179 General Precautions 180 Air Conditioner CTL55 182 OPTIONS...

Page 193: ...191 MEMO...

Page 194: ...192...

Page 195: ...193 INDEX...