D

GB

F

E

3

96156-03.2016-DGb

Contents

Page

4

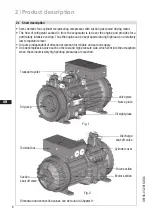

Compressor assembly

12

4.1 Storage and transportation

4.2 Setting up

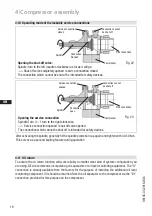

4.3 Connecting the pipelines - solder system

4.4 Connecting the pipelines - cutting ring system

4.5 Pipes

4.6 Flange shut-off valves (HP/LP)

4.7 Option: cutting ring screw joint (HP/LP)

4.8 Laying suction and pressure lines

4.9 Operating the shut-off valves

4.10 Operating mode of the lockable service connections

4.11 Oil return

5

Electrical connection

17

5.1 Information for contactor and motor contactor selection

5.2 Standard motor, designed for direct or part winding start

5.3 Basic circuit diagram for part winding start -->

with MP10

5.4 Basic circuit diagram for part winding start -->

with INT69 G

5.5 Special motor: design for direct or star-delta start

5.6 Basic circuit diagram for star-delta start with special motor -->

with MP10

5.7 Electronic trigger unit MP10

5.8 Connection of the electronic trigger unit MP10

5.9 Functional test of the electronic trigger unit MP10

5.10 Basic circuit diagram for star-delta start with special motor -->

with INT69 G

5.11 Electronic trigger unit INT69 G

5.12 Connection of the electronic trigger unit INT69 G

5.13 Functional test of the electronic trigger unit INT69 G

5.14 Oil sump heater

6 Commissioning

34

6.1 Preparations for start-up

6.2 Pressure strength test

6.3 Leak test

6.4 Evacuation

6.5 Refrigerant charge

6.6 Start-up

6.7 Pressure switch

6.8 Decompression valves

6.9 Avoiding slugging

6.10 Filter dryer

7 Maintenance

38

7.1 Preparation

7.2 Work to be carried out

7.3 Accessories

7.4 Spare parts recommendation

7.5 Lubricants

7.6 Decommissioning

8

Technical data

40

9

Dimensions and connections

42

10 Declaration of installation

44

11 Service

45