2

INSPECTION AND TROUBLE SHOOTING

2.1

Periodical inspection

These inspections should be made during the normal shut-down periods as much

as possible, so the compressor is always ready to operate when required. If, at

that time, the number of running hours slightly differs from the scheduled period

below, the inspection should nevertheless be carried out.

In this way it will not be necessary to stop the compressor at inconvenient times.

The frequency of inspections is dependent on the type of installation, operating

conditions and local regulations. In the case of automatically controlled plants,

the periodical inspection are particularly important. The table below sums up all

the points on the compressor that have to be inspected or maintained along with

inspection and maintenance frequencies.

2.2

Survey of periodical inspections

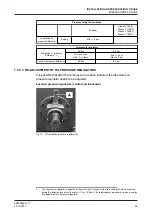

Apart from the check points in the table below, the sound produced by the

compressor also provides an indication of its mechanical condition. If abnormal

sounds are audible, their cause should be traced and removed immediately in

order to prevent serious breakdowns.

INSPECTION AND TROUBLE SHOOTING

Periodical inspection

0089288gbr_11

30.10.2017

31

Summary of Contents for Grasso V 1100

Page 6: ...0089288gbr_11 6 30 10 2017 ...

Page 8: ...0089288gbr_11 8 30 10 2017 ...

Page 10: ...0089288gbr_11 10 30 10 2017 ...