This chapter deals with the starting and stopping

of the compressor in a plant which, after the test

run, has been delivered completely ready for

operation by the installation engineer. If further

contains instructions for resetting the lubricating

oil pressure regulator and pressure safety

switches, if this should be necessary.

It is recommended to start and stop the

compressor according to a fixed procedure in

order to prevent errors and possible damage.

Especially in the case of plants with manual

control, the sequence of the necessary operations

has to come up to certain requirements.

Therefore, in the instructions given below,

reference is made, wherever necessary, to the

plant manual. If at some point the plant manual

differs form this instruction manual, the

installation engineer should be consulted.

7.1 STARTING THE COMPRESSOR

When starting the compressor, distinction should

be made between:

1)

Starting the compressor for the first time after

the plant has been out of operation for a long

period of time

(for example, on account of

seasonal standstill or maintenance operations).

for manually controlled plants as well as for those

operating automatically the starting procedure

given below should be followed exactly.

2)

Restarting the compressor in an already

operational plant.

In the case of manually operated plants only the

instructions mentioned under b, e, f, h and j need

to be followed, as well as those included in the

plant manual. In the case of automatically

operating plants, this starting procedure is

incorporated in the control system and therefore

does not generally require any special care.

The starting procedure is as follows:

a) Consult the plant manual.

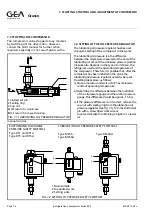

b) Make sure that the oil level in the crankcase is

correct (see Chapter 8) and check whether the

shaft seal housing and both oil filter housings

are filled with oil (especially after maintenace

work).

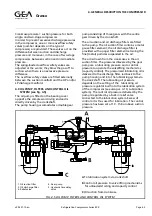

c) Check whether the suction stop valve and the

stop valve in the return line of the oil separator

are closed.

d) Check whether the discharge stop valve, the

pressure gauge valves and (in the case of

two-stage compressors) the stop valves in the

intermediate pressure line are open.

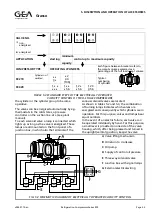

e)

In the case of a compressor provided with a

manually operated capacity control:

set the oil

distributor to position 1:

In the case of a compressor provided with an

electrically operated capacity control:

Check

whether the manual control lever of all solenoid

valves is in its lowest horizontal position.

f) (not within 3 minutes after the compressor was

stopped) Start the compressor and check

whether the oil pressure increases.

g) Slowly open the suction stop valve, thereby

watching the suction pressure which may not

exceed 6 bar (on gauge). Also be careful that

no liquid hammer occurs, especially in plants

with lower suction lines.

h)

In the case of single-stage compressors with

capacity control:

After the compressor has

started up and one or more cylinders have

automatically become operative, cut in the

other cylinders as and when required, thereby

watching the maximum allowable amperage (it

must not be higher than the amperage stated

on the motor).

In the case of two-stage compressors with

capcity control:

3-4 minutes after the

compressor has started and one HP-cylinder

becomes operative automatically, cut in the other

cylinders stepwise, thereby watching the

discharge temperture on both the HP- and LP-side

(max. 140 °C), the intermediate pressure (max.

saturation intermediate temp. +10 °C) and the max.

allowable amperage (not to be higher than the

amperage stated on the motor nameplate).

j) (if cylinder jacket cooling is applied). Check the

cooling water flow.

k) Adjust the opening of the pressure gauge stop

valves so that the gauge pointers do not

vibrate any longer.

l) (not during the running-in period of the plant).

Open the stop valve in the return line of the oil

separator.

CAUTION! In case of reduced cooling load it is

not allowed to cut out so many cylinders

of a

compressor already operating in two stages that

only the HP-cylinder is still operating. At least

two LP-cylinders should remain operative.

Refrigeration Division

Grasso

7. STARTING, STOPPING AND ADJUSTMENT OF COMPRESSOR

v002.97.10.en

Refrigeration Compressors Series RC9

Page 7.1