44

PowerVac

®

5kV Vertical Lift

Chapter 12. Repair and Replacement

12-1 General

The following information covers in detail the

proper method of removing various parts of the

breaker in order to make any necessary repairs.

This section includes only those repairs that

can be made at the installation site, or parts of

the breaker that are most subject to damage.

Important:

Upon completion of any kind of re-

pair work, all interrupter and mechanism adjust-

ments must be checked.

Refer as needed to sections on mechanical and

electrical adjustments.

12-2 Replacement of

Interrupter (Assemblies)

Interrupters are supplied in complete interrupter

assemblies which include the vacuum inter-

rupter mounted in the interrupter support, and

primary studs. It is recommended that the inter-

rupter NOT be removed from the assembly in

the field.

CAUTION:

DO NOT ATTEMPT TO REMOVE

OR REINSERT THE VACUUM INTERRUPTER

IN THE INTERRUPTER SUPPORT ASSEM-

BLY. SPECIAL TOOLS AVAILABLE ONLY AT

THE FACTORY ARE REQUIRED TO PREVENT

DAMAGING THE VACUUM INTERRUPTER

BELLOWS.

1.

To remove the ML-19 element from the main

truck or frame.

a.

Remove rear cover; disconnect surge

suppressors; remove rear interphase

barrier support and interphase.

b.

Disconnect element-to-primary bus at

the element end.

c.

Detach the Secondary Connecter

Bracket. Be sure to mark its location and

retain the shims for re-installation. De-

tach the MOC Driver from the Frame.

d.

Properly support the ML-19 element

Remove (4) bolts at top of frame

(2) bolts at sides

e

. Lift element clear of frame.

2.

Close the breaker element and remove the

coupling clamp (Figure 23, Item 6). Hold

the hex projection (Figure 23, Item 7) at the

bottom of the operating rod insulator with

a 1 inch wrench and loosen the adjcent

lock nut with a 3/4 inch wrench. Screw

down the lock nut and the operating rod

insulator until clear of interrupter rod.

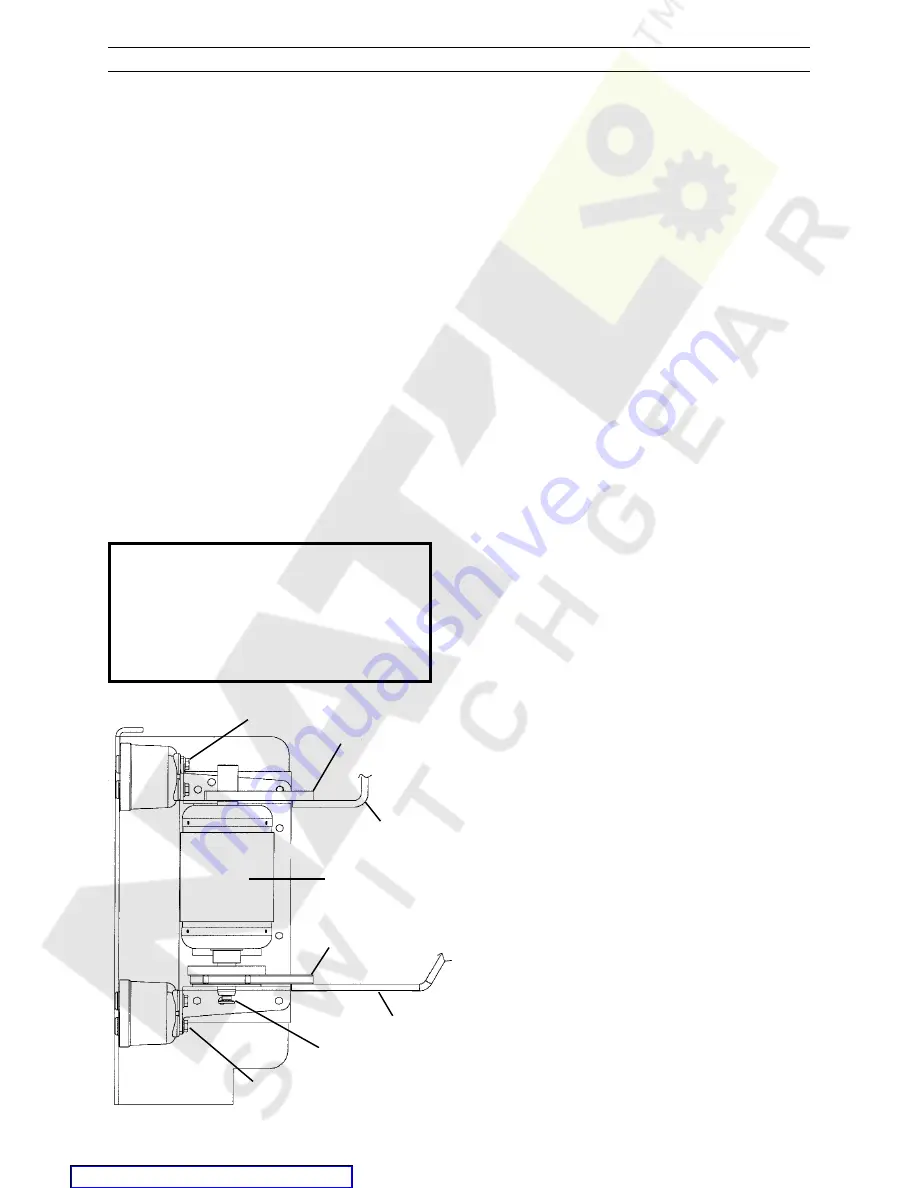

Figure 43. Pole Assembly

1. Mounting Bolts

2. Bus Runbacks

3. Primary Bus

4. Secondary Bus

5. Vacuum Interrupter

6. Movable Stem (clamp)

1

2

2

3

4

5

6

1