12

4-4 Check for Proper Interlock

and Trip-free Functions Before

Energizing the Breaker

WARNING:

THE PRIMARY EQUIPMENT

SHOULD BE COMPLETELY DE-ENERGIZED

WHILE THE TESTS ARE IN PROGRESS.

DO NOT INSTALL OR REMOVE THE

BREAKER OR MAKE ADJUSTMENTS UN-

LESS THE BREAKER IS OPEN.

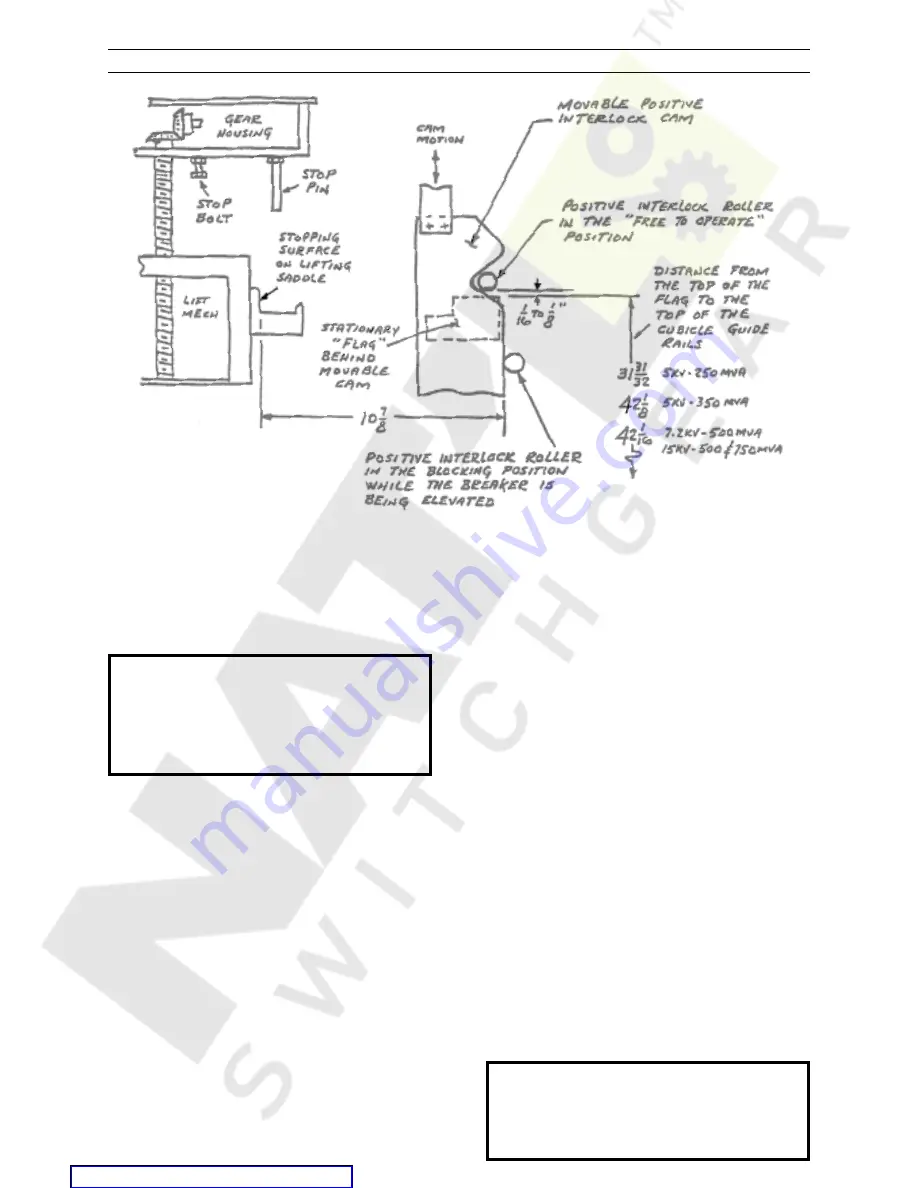

To test the function of the positive interlock sys-

tem and trip free function, the following checks

should be made:

1.

Verify that red grease has been rubbed on

the silvered portion of the breaker studs,

ground shoe, and 16 secondary coupler

pins, forming a thin coating for contact

purposes.

2.

Before inserting the New VL vacuum

breaker into the cubicle, verify the cubicle

interlock position by measuring the dis-

tance between (Figure 6) the movable posi-

tive interlock cam to the back of the lifting

saddle of the racking mechansim. This dis-

tance should be 10 7/8” minus 0, plus

1/16”.

Figure 6. Positive Interlock system

PowerVac

®

5kV Vertical Lift

Chapter 4. Installation

3.

Lower the elevating mechanism lifting

brackets until the lifting brackets are in the

fully lowered position. The breaker should

then enter the housing freely. After first

assuring that the breaker is in the open

position, push the breaker into the unit until

it rests against the rear of the front lifting

saddle of the elevating mechanism.The

clearance between the interference block

on the breaker and the interference block

on the interlock mechanism should be from

.063" to .125".

4.

With the breaker in the lowered position,

the positive interlock roller engages in the

lower Vee notch, in the interlock cam plate.

The breaker should be in the opened posi-

tion and the closing springs discharged

as indicated by the flag indicators. (Figure

1, items 4 and 6) Using the manual charg-

ing handle, charge the breaker. Then close

the breaker and recharge. (Figure 7, Item

1). With the elevating motor switch in a

neutral position engage the clutch to verify

the operation of the positive interlock. The

springs will discharge and the breaker will

open.

NOTE:

TABLE 3, FIGURES 6, 52, 53, AND

54 HAVE BEEN PROVIDED TO FAMILIAR-

IZE THE OPERATOR WITH THE EQUIP-

MENT RACKING SYSTEM AND TROUBLE-

SHOOTING.

(-0, + 1/16”)