Chapter 4. Using Special Features

64

Model PM880 Portable Hygrometer User’s Manual

4.8.3b Entering a Label for the Table

1.

The Table box should be highlighted. Press

[ENTER]

to open the

drop-down menu.

2.

Use the arrow keys to scroll to the desired table number and press

[ENTER]

.

3.

Use the arrow keys to move to the Table ID box and press

[ENTER]

. A

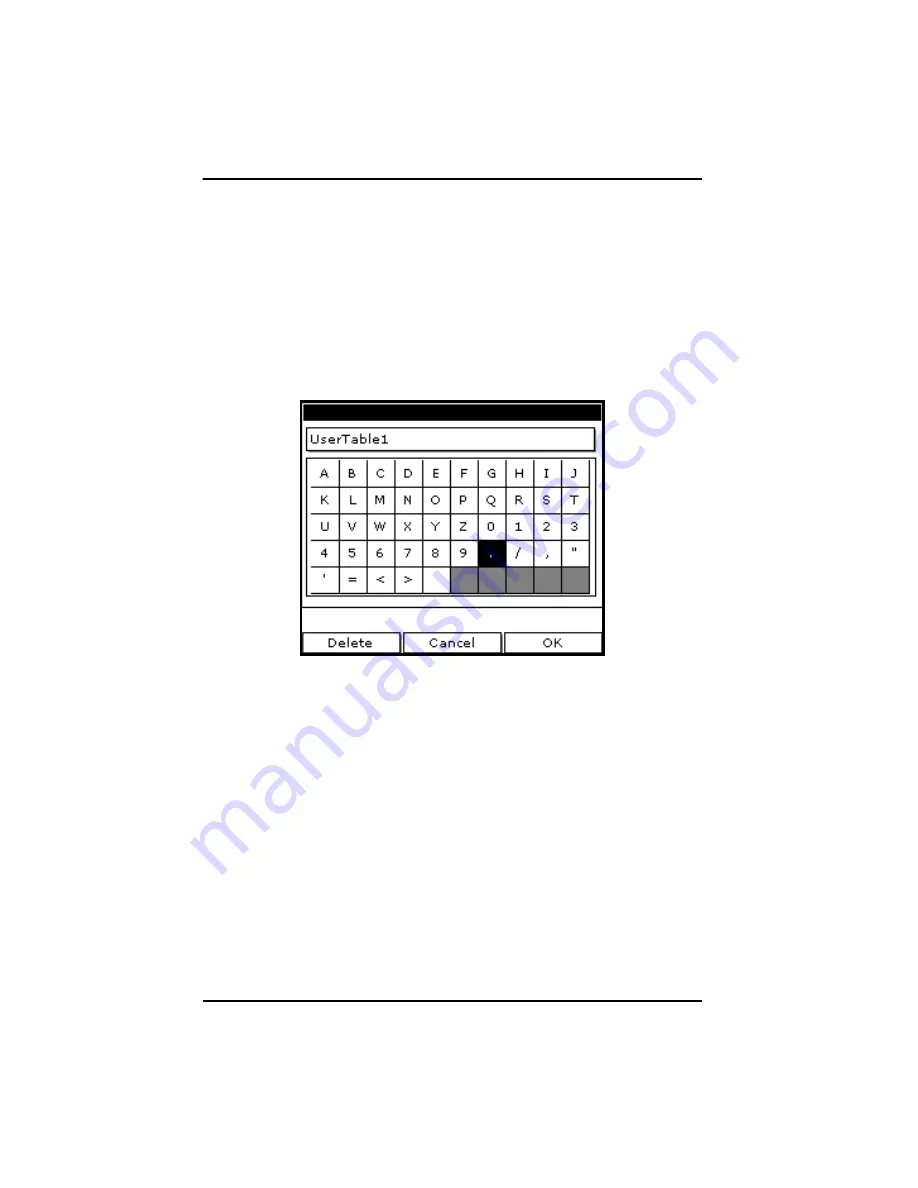

screen similar to Figure 28 appears.

Figure 28: Text Creation Window

4.

Use the arrow keys to scroll to the desired character and press

[ENTER]

.

Press

[F1]

(

Delete

) to delete any unwanted letters or numbers. Press

[SEL]

to view the three screens with the available characters and

symbols for creating a label for the table.

5.

Repeat this procedure until you have created the desired label for the

table of up to thirty-two characters.

6.

When you have finished, press

[F3]

(

OK)

.

Note:

It is not necessary to enter the “#Data Points” or “Max Points” text

boxes. The meter automatically enters this data.