SECTION 9-Fused Breakers

There are two types of fused breakers ; AKRU 30, 800

ampere frame and AKRU 50, 1 600 ampere frame. Except

for the open fuse lockout device and the i ntegrally

mounted fuses on the u pper studs, the AKRU-30 and -50

breakers are identical to the unfused AKR-30 and -50

models. Overcurrent trip devices are the same for both

types.

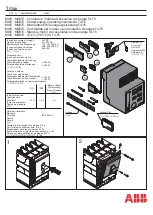

9.1 FUSE SIZES AND MOUNTING

Table 6 lists the range of fuse sizes available for these

breakers. The Class

L

fuses are mounted as shown in Fig .

51 . Other than the 800A size, which has a single mounting

hole per tang , each Class L fuse tang has two holes sized

for one-half inch diameter bolts.

Class

J

fuses rated 300 thru 600A have one mounting

hole per tang. The 300, 350 and 400A sizes require copper

adapter bars per Fig. 52.

All 1f2-1 3 fuse mounting bolts should be torqued to 200-

350 in.

-

lb. The %-1 1 bolts which attach the C shaped fuse

adapters to the breaker studs should be torqued to 300-

525 in. -lb.

FIG . 51 - TYPICAL MOUNTING CLASS L

FUSES

9.2 SPECIAL 2500A FUSE FOR AKRU-50

This fuse provides a melting time-current characteristic

that coordinates with 1 600A trip devices. Com pared physi

cally with a 2500A N EMA Class

L

fuse, the special fuse is

more compact (shorter) ; its tangs are specially configured

and offset to achieve the required pole-to-pole fuse spac

i ng ; a special primary disconnect assembly mounts directly

on the outboard tang of the fuse. Considering their unique

mounting provisions, when replacing these fuses the fol

lowing procedure should be adhered to ( Refer to Fig . 53):

a) Remove the primary d isconnect assem bly from the

fuse tang, accom pl ished by first loosening the two keys

via their holding screw and pulling them u pward and out.

After the keys are removed , pull the d isconnect assem bly

off the end of the fuse tang.

NOT E :

This rem o val does not disturb the

disconnect's clamping force adjustment.

b) Remove the upper barrier.

c) Detach the inboard end of the fuse by removing the

two 1 /2 inch - 1 3 bolts. A ratchet and socket with a short

extension will be requied.

d) Remove the heat sink.

e) Remove the fuse.

f) I nstall the new fuse by reversing the disassembly

procedure. Ensure that the mating faces of the fuse and

heat sink are clean .

ADAPTER BARS (COPPER)

FIG. 52 - 300 THRU 600 AMP CLASS J

FUSE MOUNTING

41

www

. ElectricalPartManuals

. com