OUTDOOR TECHNICAL OVERVIEW

ENGLISH

B-8

Operations

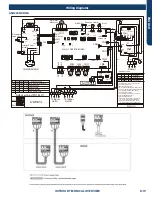

Comp-

ressor

Discharge temp.

●

sensor

Oil

separator

Capillary tube

Ø2.7*Ø1.0*1400

High pressure

switch

4-way valve

Pipe sensor

Toci

Suction temp.

sensor

Ts

Low pressure

switch

Accumulator

Gas

service valve

Outdoor

heat

exchanger

temp.

sensor

FAN-OUT

Outdoor

ambient

temperature

sensor

Ta

Defrost

sensor

Td

Distributor

Strainer

EEV

O

Receiver

Liquid

service valve

5/8

3/8

Unit A liquid pipe temp. sensor

Tc2

Strainer

EEV

A

Indoor unit A

Unit B liquid pipe temp. sensor

Tc2

Strainer

EEV

B

Indoor unit B

Unit C liquid pipe temp. sensor

Tc2

Strainer

EEV

C

Indoor unit C

Unit A gas pipe temp. sensor

Tc1

Unit B gas pipe temp. sensor

Tc1

Unit C gas pipe temp. sensor

Tc1

Indoor unit A

Indoor unit B

Indoor unit C

4-way valve coil:

OFF

ON

Refrigerant flow in cooling

Refrigerant flow in heating

FAN-IN

Indoor

ambient

temperature

sensor

Indoor

heat

exchanger

temp.

sensor

On a call for heating, the indoor unit will send the room temperature and set-point requirement to the outdoor unit PCB via the

data signal wire path. The data travels from the indoor unit to the outdoor unit via the wire located on terminal 3/C. The indoor

unit louvers will open. The fan will not start until the coil has warmed sufficiently to avoid cold drafts.

EEVs serving indoor circuits will step to the standard opening. The outdoor EEV opens to a position based upon the outdoor air

temperature.

The 4-way valve will energize and the outdoor fan will start. The compressor starts at a slow speed and will increase based upon

demand. The indoor fan starts after the indoor coil is warm enough to avoid circulating cool air.

With the compressor operating, refrigerant will begin to flow throughout the refrigeration circuit.

The operating frequency of the compressor will be displayed on the Service Monitor Board.

When the compressor starts, hot gas will flow into the oil separator. Oil will be trapped in the separator and returned to the

suction inlet of the compressor via the capillary tube assembly low pressure path.

1

2

3

4

5

6

2

Te

Heating Mode Sequence of Operation

Summary of Contents for AB09SC2VHA

Page 2: ...Oct 2020 Manual release Revision History ...

Page 12: ... This page intentionally left blank ...

Page 45: ...WALL MOUNT TECHNICAL OVERVIEW ENGLISH Topic Title C 9 Wiring Diagrams ...

Page 68: ... This page intentionally left blank ...

Page 78: ... This page intentionally left blank ...