T E C H N O L O G I E S

Fig.1

Fig.2

Fig.3

The Combi sensors which have an LCD display fitted also incorporate 3

reed switches which can be activated using external magnets through the

glass window of the flameproof XDIwin enclosure.

These magnets do

not act instantly and have to be in close proximity to L, M and

R on the front display for a few seconds to activate a software

setup function.

The left magnet

enters the Auto zero ON or OFF menu.

This allows small drift changes in the sensor to be compensated for

but is not operational when the sensor readings are greater than 5%

of full scale. Therefore auto zero is inactive when a larger gas reading

is present. When the remove magnets message appears, move the left

magnet away and then the display shows if auto zero is ON or OFF. The

left magnet puts auto zero ON and the right magnet turns it OFF. With

no magnets present, the display will return to normal after a few seconds

timeout.

The right magnet

allows the CAN address of the sensor to be

changed. When the ADDRESS menu is displayed with a prompt to

remove the magnet, and then the display shows the address and that the

right magnet decreases it whilst the left magnet will increase it. This is then

stored in internal non volatile memory and the display will automatically

revert to normal operation.

The centre magnet

is used to inhibit the sensor. As with the left and right

magnet functions the display requests that you remove the magnet and

then the state of the inhibit appears on the LCD. The left magnet then puts

the sensor into inhibit whilst the right magnet removes it. An amber LED on

the front panel under the LCD flashes when the sensor is inhibited. When

all magnets are removed, the display will revert to normal operation.

The left and right magnets together allow the calibration menu

to be used.

Removing both magnets as instructed on the LCD presents the first part of

this multi menu which is ZERO. With no gas present use the left magnet

to increase the reading and the right magnet to decrease to achieve a

zero reading on the display. A timer is displayed on the LCD and when

this reaches 0, the next menu is displayed. This timer is 15 seconds

approximately and is reset back each time a magnet is near. Waiting till

timeout is acceptable but this timeout can be speeded up by placing a

magnet near to the centre position.

SPAN is the next part of the menu and gas should be applied to the

sensor at this time.

The left magnet increases the gain and the right magnet reduces gain. The

actual sensor value can be seen on the display to rise or fall respectively.

LOW ALARM is the next menu and left and right magnets increase and

decrease this value.

HIGH ALARM is next followed by OVER RANGE alarm.

The direction of the alarms is displayed as ^ for rising and v for falling but

these can be changed using left and right magnets together.

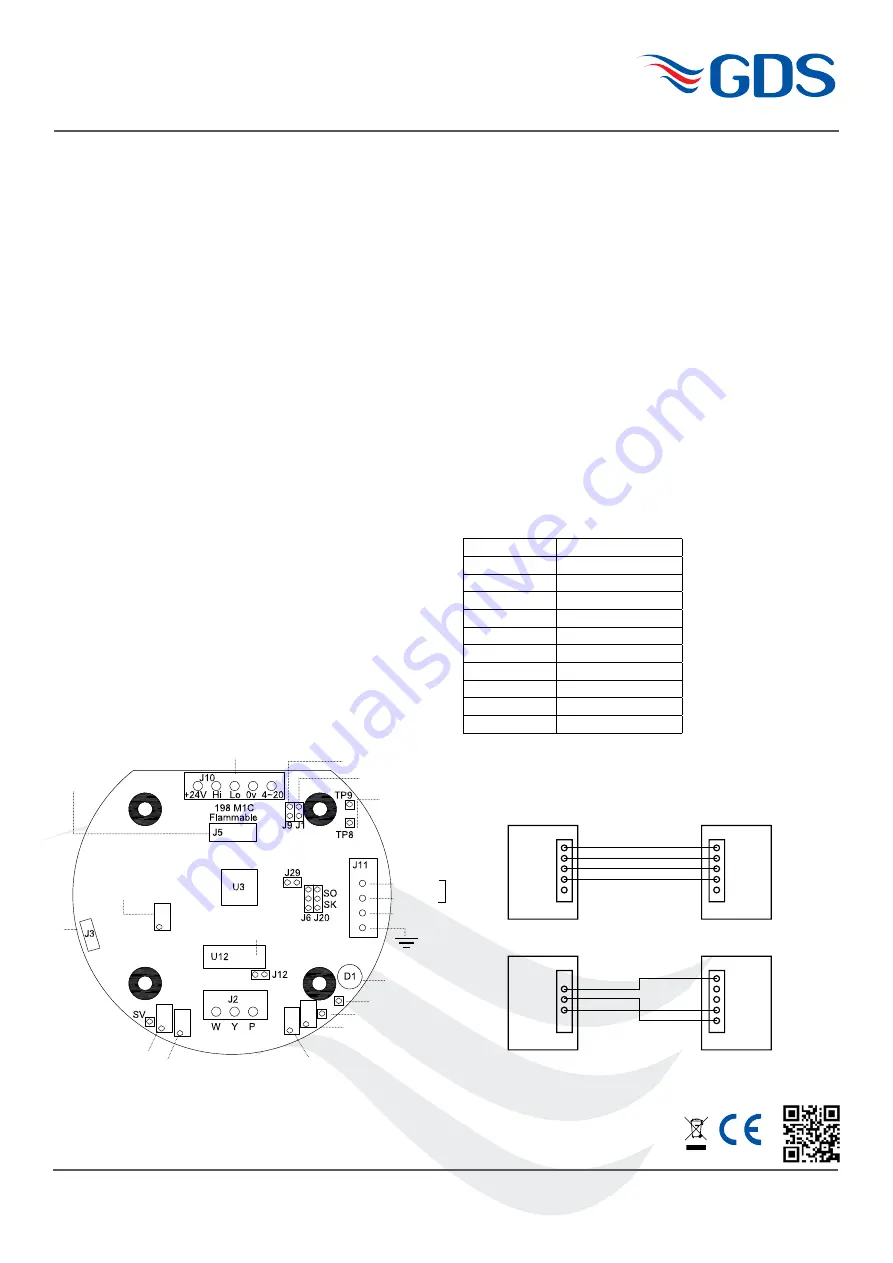

Sensor cell supply table

CAT300A

2v/300mA

CAT170A

2v/175mA

SEM-1

4v/170mA

GDS PRIME

4v/70mA

CAT335C

2.5v/335mA

THE300A

2v/300mA

SS10

2v/175mA

CAT335A

2.5v/335mA

CAT335B

2.5v/335mA

CAT100A

2v/100mA

CAT165

2.2v/165mA

EOL

CAN

4-20

MPU

FAULT

TP1

OV

TP11

TP9

TP5

TP8

TP10

198M1C

ISS M

TP

7

ZERO

ZERO

TP12

DISP

MPU active LED

(Flashing)

Fault LED

Sens V Test Point

TP7 + TP12

Sensor cell input

Sensor Volts

(RV3)

Zero

(RV2)

Span

(RV1)

4mA

(RV4)

Sensor Zeroing LEDs

CAN Transmitting LED

4-20mA SInk/Source

4-20mA Test

Jumper

End-of-line Jumper

Relay/Win Ribbon

LCD Contrast

Win Only

RS232

PC Data In/Out

Win Data Ribbon Cable

4-20op Test Points

FIELD TERMINALS

HI LO

24V Can+ Can- OV 4-20mA

24V Hi

Lo OV 4-20

mA

P

Y

W

Control Unit

CAN 1 or 2

Sensor

Addressable

+24

Hi

Lo

0v

4~20mA

+24

Hi

Lo

0v

Control Unit

4~20mA Input

Sensor

3-Wire Direct

4~20mA Signal

+24

Hi

Lo

0v

4~20mA

+24

Sig

0v

EOL

T

FAULT

MPU

SK

SE

204M1C

ISS M

CONTRAST

Fault LED

Gas Type Header

Sensor cell input

20mA

Span

(RV2)

4mA

Zero

(RV1)

Sensor 4-20mA Routing Configurations

(see diagram)

CAN Transmitting LED

4-20mA Test

Jumper

Relay/Win Ribbon

LCD Contrast

Win Only

End-of-line Jumper

+24V Test Point

(w.r.t 0V)

+24V

RS232

PC Data In/Out

Win Data Ribbon Cable

4-20mA Test Pins

4-20mA Sink Source

External 4-20mA Input

(eg. Infrared)

+24V O/Pt

(eg. Infrared)

FIELD TERMINALS

HI LO

24V Can+ Can- OV 4-20mA

24V Hi

Lo OV 4-20

mA

P

Y

W

Mainboad to Sensor wiring

Sensor Jumper configuration

Control Unit

CAN 1 or 2

Sensor

Addressable

+24

Hi

Lo

0v

4~20mA

4~20 IN

SO

SK

+24

Hi

Lo

0v

Control Unit

4~20mA Input

Sensor

3-Wire Direct

4~20mA Signal

+24

Hi

Lo

0v

4~20mA

+24

Sig

0v

Control Unit

4~20mA Input

Sensor

2-Wire Direct

4~20mA Signal

+24

Hi

Lo

0v

4~20mA

+24

Sig

0v

Control Unit

CAN 1 or 2

Sensor

Addressable 4~20mA Input

+24

Hi

Lo

0v

4~20mA

+24

Hi

Lo

0v

4~20 IN

SO

SK

4~20 IN

SO

SK

4~20 IN

SO

SK

ange

t magnets

Using magnets (set up)

Display

Contrast

Field terminals

Relay PCB

Connector

Display PCB

Connector

Test

Test Pins

24v DC

OV

FLT

OUT

IN

AG

Zero LED

ADDR

4mA

20mA

Sensor

Zero

Sensor Volts

Comms

Port

EOL

Vo

This document is not contractual and the equipment specification may be modified at any time without prior notice.

E:

T:

+44 (0)113 286 0166

GDS TECHNOLOGIES LTD

|

FUSION POINT

|

ASH LANE

|

GARFORTH

|

LEEDS

|

LS25 2GA

|

UK

Technical Sheet ref C893Sv.14

198D1C