Expert Pro User Manual

The Control Panel 3-1

Chapter 3 The Control Panel

This chapter describes the button operations with the LCM menu flowcharts of Expert Pro. When

the cutting plotter is ready for use as described in Chapter 1 & 2, all functions are under default

parameters.

3.1 The LCD Panel

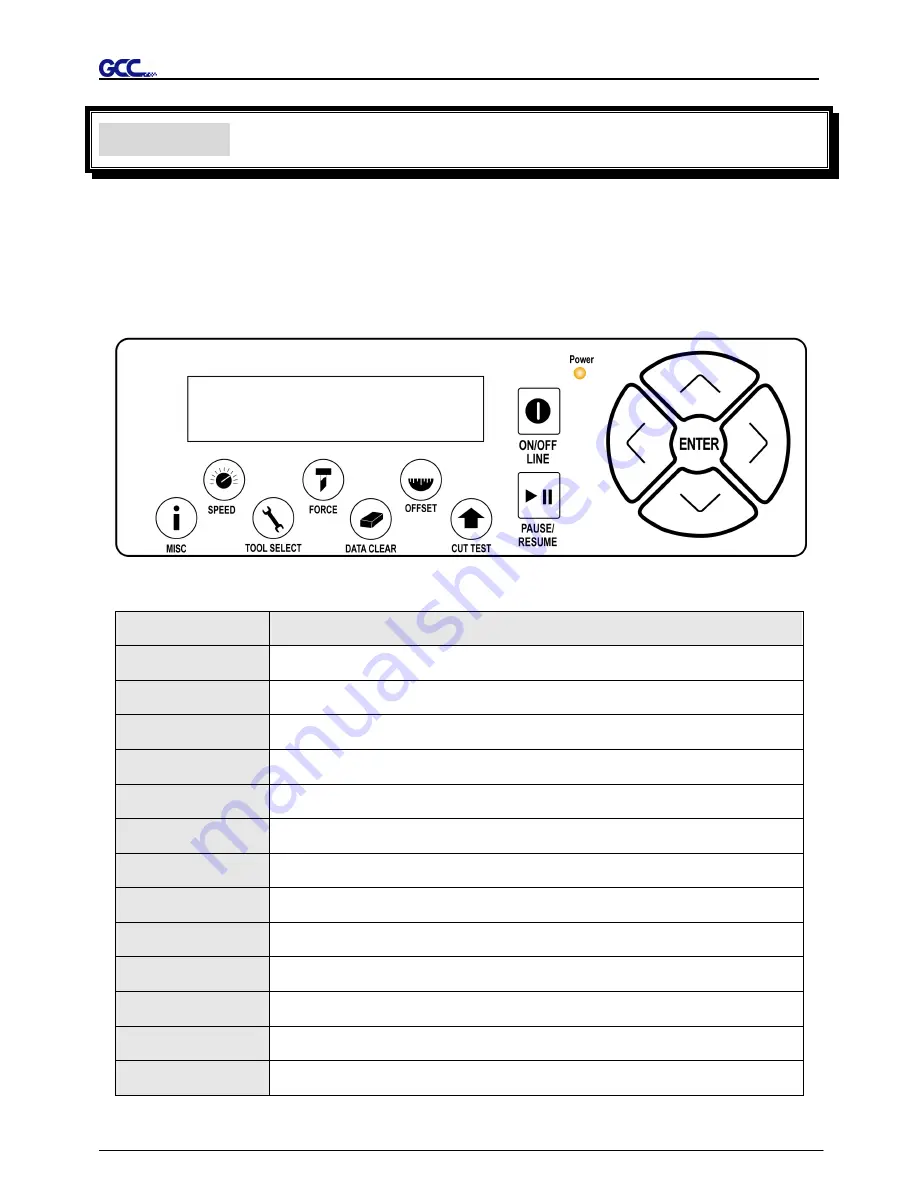

< LCD Control Panel on Expert Pro series >

Key

Function

LCD Screen

To display functions and error messages.

Power LED

To indicate the power status ( light up: power on; light off: power off )

4 Arrow Keys

To move position, select function, or change setting.

ENTER

To set item or register the immediately preceding input value.

PAUSE/RESUME To temporarily halt cutting process or to continue

ON/OFF LINE

To switch modes, stop cutting job, or abort changes of settings.

OFFSET

To adjust the value of blade’s offset.

FORCE

To adjust the value of cutting force.

SPEED

To adjust the value of cutting speed and quality.

CUT TEST

To perform cutting tests on different media.

DATA CLEAR

To clear up buffer memory.

TOOL SELECT

To select tools.

MISC

To set up functions.

Please see details in

“3.4 Menu Items”