R ECEIVING & INSTALLATION

RECEIVING

Most ClearAir

™

units are shipped in one piece. However, some

units, because of size or special jobsite conditions, may be

shipped in multiple sections. Follow the instructions that are

provided with the unit to join sections back together. If the unit

includes media bed odor control, the KOR48/carbon odor

control media is packaged separately. Verify against the

shipping documents that you have received all items and note

any shipping damage, obvious or hidden, to your carrier and

on your Bill of Lading. If damage is found, immediately file a

claim with the transport company. All units are thoroughly

inspected and fully operation tested at the factory prior to

shipment.

Verify that the electrical and air flow ratings on the unit name

plate agrees with jobsite requirements. If a contradiction arises

notify the factory prior to proceeding with installation.

SAFETY CONSIDERATIONS

Installing and servicing the ClearAir

™

unit can be hazardous

due to the presence of electrical components. Only trained

and qualified service personnel should install or service this

equipment.

Untrained personnel can perform basic maintenance, such

as cleaning and replacing filters. All other operations should

be performed by trained service personnel. When installing or

servicing, observe precautions in literature and on tags and

labels attached to unit.

Follow all safety codes. Wear safety glasses and work gloves.

Use quenching cloth for brazing operations. Have fire

extinguisher available. Read these instructions thoroughly.

WARNING

Before installing or servicing system, always turn off main

power, exhaust and supply fans to system. There may be

more than one disconnect switch.

Electrical shock can cause

personal injury or death

.

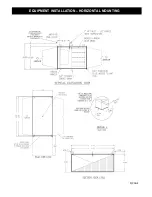

RIGGING

All units are provided with a minimum of four (4) lifting points,

or (2) continuous mounting flanges for rigging attachment.

WARNING: Use all lifting points provided (Refer to Page 10).

Spreader bars are mandatory to prevent contact and damage

to the unit by lifting hooks, straps, cables, or chains. Consult the

mechanical or structural engineer before moving the unit

across the roof deck. Hanging weight is 375 lbs. for the 1x1

and 540 lbs. for the 2x1.

INSTALLATION CODES

This unit requires external plumbing and electrical connections

to be made in the field. It is recommended that the Authority

Having Jurisdiction (AHJ) be consulted regarding local codes

and installation procedures. Gaylord Industries is not

responsible for obtaining necessary approvals and permits

which may be required for installation, nor is it responsible for

verifying that the unit has been installed in accordance with

national, state, and local codes. In the absence of locally

adopted codes use the latest editions of the national electrical

code and the uniform/International mechanical code.

Connections of the exhaust duct to the inlet and outlet of the

ClearAir

™

unit must be fully welded to comply with NFPA-96.

INSTALLATION PRECAUTIONS

1. The services of qualified contractors are essential for safe

and proper installation of this equipment.

2. The air volumes and external static pressures that are

listed on the unit are for the middle of the operating range of

the filters. The initial air volume should be at least 10% higher

than the listed CFM. As the filters load up the air volume will

drop. This is inherent to this type of unit. If the unit is set up

at or below the design CFM, as the filters load up, the kitchen

hood may experience smoke loss problems. Please consult

the factory if you have questions.

3. The unit is designed for installation on a level surface.

4. When installed in an enclosed space a fire-rated

enclosure may be required for the unit and associated duct

work. Consult the Authority Having Jurisdiction.

5. Consult the Authority Having Jurisdiction (AHJ) regarding

requirements covering the point of termination of the exhaust

outlet of this unit. Minimum distances must usually be

maintained between the exhaust outlet and any outside air

intakes and/or adjacent structures or property lines.

6. Do not apply power to the unit until all electrical

connections have been made and a pre-start-up

preliminary inspection has been completed.

7. Allow a minimum of 36 inches clearance in front of the

filter access door and electrical compartment door for ser-

vice and routine maintenance.

SHORT TERM STORAGE

Units that include media bed odor control are provided with

KOR48/carbon media which is shipped separate from the

unit. KOR48/carbon media must be stored in a dry place with

less than 95% relative humidity.

LONG TERM STORAGE (OVER ONE MONTH)

Units must be covered and stored in a warm dry location to

prevent excess moisture from accumulating in the odor media

and final filters.

4|PAGE