4

Fig 2

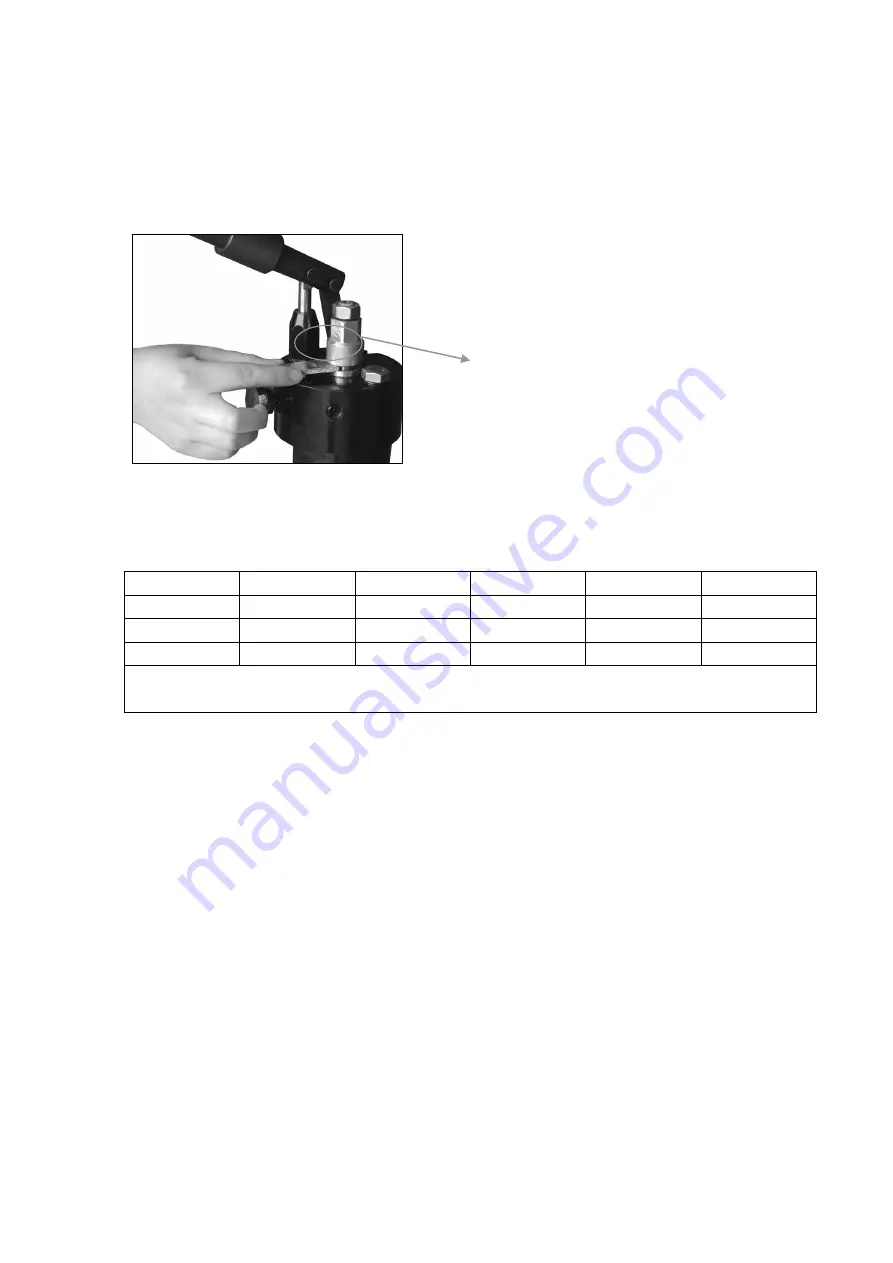

3. Insert the index plate to the gap below the nut, rotate the nut till it touches the index plate, lock

the depth adjusting nut by tightening the top nut close to it.

Fig 3

Forming the Roll Groove

Pipe wall thickness cannot exceed the maximum

wall thickness specified in the “Pipe Maximum and

Minimum Wall Thickness” Table. Do not use to groove 8” schedule 40 steel pipe harder than 150 BHN.

Pipe size

Min

Max

Pipe size

Min

Max

2 1/2

”

.083

.203

4

”

.083

.237

3

”

.083

.216

6

”

.109

.280

3 1/2

”

.083

.226

All dimensions are in inches.

NOTE! Groove diameter should be measured using a Diameter - tape.

Periodically check groove with a Diameter-Tape or similar measuring device.

Roll Grooving Tips

1. If pipe tends to “walk off” drive roll, increase offset dimension.

2. If drive roll flange shaves pipe end, decrease offset dimension.

3. If pipe end flare is excessive, lower pipe end to level with roll groover.

4. If pipe wobbles and/or “walks off” the drive roll, raise pipe end to level with roll groover.

5. Short lengths of pipe (under three feet) may require slight pressure to maintain the degree offset

dimension.

Measure out the depth

Summary of Contents for RG6C

Page 7: ......