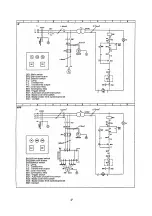

Fig.6

3.2 INSTALLATION

Inspect the machine to ensure that it is not damaged and

proceed with its positioning.

When choosing the machine position it is recommended

to consider:

·

That the chosen position is not humid and that it is

sheltered from atmospheric agents;

·

That the surface is perfectly level, it is a non-slip surface

and that its bearing capacity is suitable for the weight of

the machine;

·

That there is adequate, free space around the machine;

·

That the location in which the machine is installed is

guarded or enclosed, to prevent children or

unauthorized persons from accessing the machine;

·

That suitable, approved lighting is provided;

·

That it is located near a main switch equipped with an

overload cutout;

·

That the power supply system is equipped with earthing

which complies with the relevant standards;

·

That the ambient temperature ranges between 0

o

C and

45

o

C;

·

That the workplace is not in an explosive atmosphere.

After positioning the machine proceed ad follows:

·

Make the position of the fixing holes (16 fig.1);

·

Lift the machine and place it to the side;

·

Use an appropriate size bit to drill the holes in the

ground and insert the threaded screw anchors;

10

·

Reposition the machine with its base in its position then

secure the base with the screws provided.

If the machine is supplied without a base, then it must

be secured by means of the two holes (15 Fig.1) to a

special structure capable of supporting the weight of

the machine and any unbalancing created when using

it.

WARNING!

The Manufacturing Company declines any

responsibility for damages caused by incorrect

installation and the use of unsuitable bases.

3.2.1 CLEANING THE MACHINE

After positioning the machine (with the work bench level,

and before making the connections) clean off all the

protective oils on the painted and unpainted surfaces with

detergent or mineral naphtha.

These liquids must not be sprayed on; use a cloth

dampened with the liquid, then dispose of the cloth in

accordance with the relevant antipollution regulations.

3.2.2 CONNECTIONS

·

Ensure that the mains voltage corresponds to that of the

machine motor indicated on the identification plate (17

Fig.1)

·

Connect the line cable of the machine to an electrical

board equipped with an automatic main switch (magneto

thermal type), with earth connection ad stipulated by the

safety standards in force, capable of protecting the

machine from overloading and short-circuiting.

·

Ensure that the cutting band rotates in the direction of the

arrow on the safety guard which covers it and that the saw

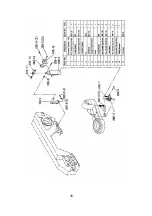

teeth are facing the correct direction (Fig.6).

Remove the handgrip control and the rod with bar-stop from

the supplied accessories and proceed as follows:

Rod with bar-stop

·

Insert the threaded rod into its seat (14 Fig.1) and lock it.

Coolant

·

Pour the coolant, which consists of water and emulsifiable

oil (13 l.) into the recovery tank (13 Fig.1). Dilute the

Summary of Contents for BS260

Page 5: ...4...

Page 6: ...5...

Page 18: ...17...

Page 22: ...21...

Page 23: ...22...

Page 24: ...23...

Page 25: ...24...

Page 26: ...25...

Page 27: ...NOTES Page 27...

Page 28: ...Distributed by Garrick Herbert Pty Ltd KIRRAWEE NSW Australia www garrickherbert com au...