9

5.

Getting to work in the field

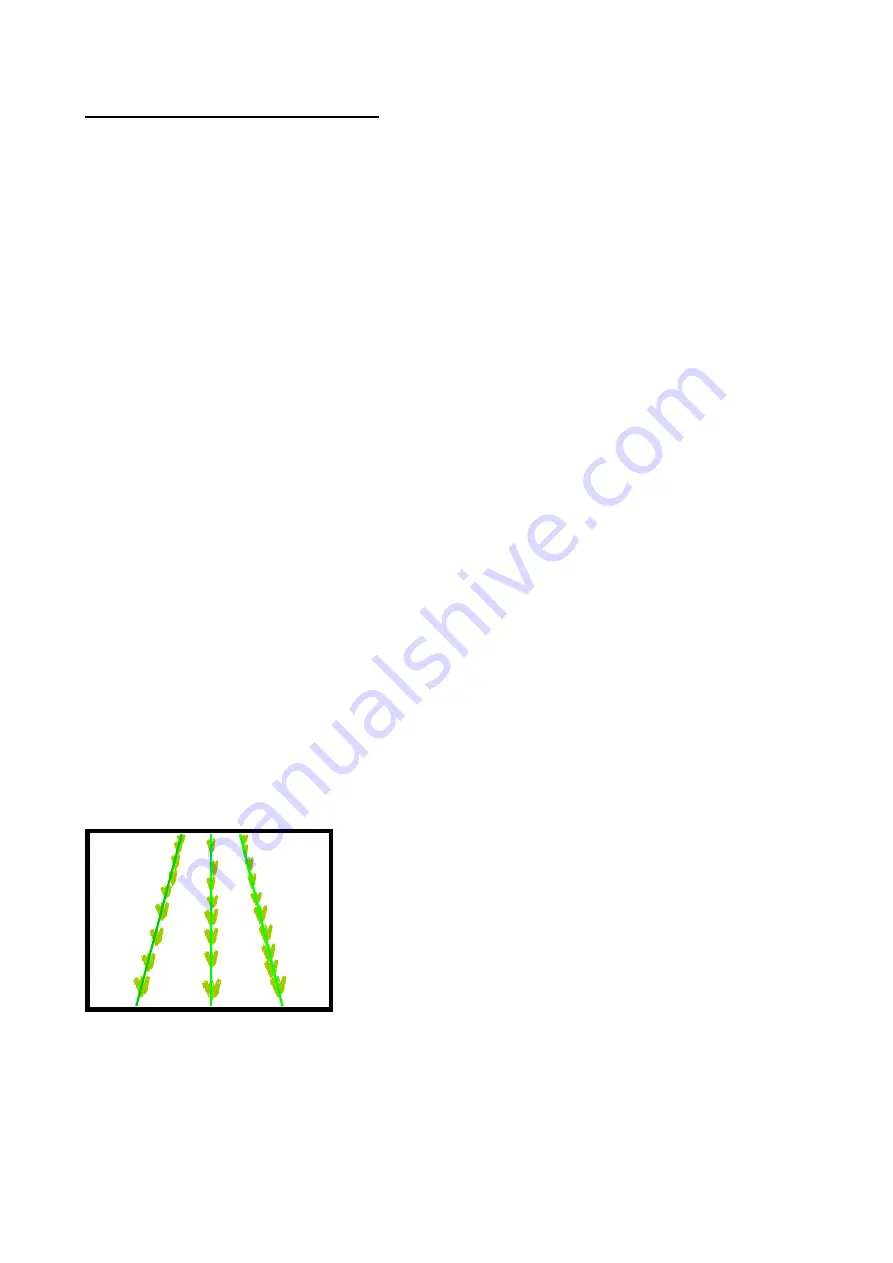

The most important procedure to ensure good guidance is to match the template, as illustrated by

the green lines, to crop rows as they appear in the live video image. The following steps outline

how to get the best match and hence achieve good guidance.

Tip

For the first few hundred meters of running after commissioning Robocrop learns a term known as

camera skew (see section 7.3) Camera skew compensates for minor errors in camera orientation

in the horizontal plane. Wherever possible we recommend that set up runs (step 4) are conducted

in crop showing the clearest rows available so that camera skew is learned as quickly and

accurately as possible. High visibility rows also help manual alignment checks (step 3). We also

recommend that side slopes and intense partial shadows are avoided during initial running. Once

set up is complete more challenging situations can be tackled. It is also possible to view the

current value of camera skew and reset it manually (see section 7.3).

Step 1

– Selecting configuration file and crop size

From the working screen press button labelled with a spanner symbol to reach the setup screen.

The top line of this screen indicates crop size (height) settings under categories of small (<5cm)

medium (5-15cm) and large (>15cm). The second line lists the available configuration files. Use

the buttons labelled with arrows to ensure that the highlighted options correspond to the crop and

crop size being used for setup and initial running.

Check details at the bottom of the screen to ensure selected configuration file settings match crop

and camera geometry.

If either crop geometry or configuration settings are not correct refer to section 7 for instructions on

making the necessary changes.

To return to the working screen by pressing the button

labelled “OK”.

Step 2

– Checking camera height and inclination angle in the field

Draw into the crop and set the cultivator down onto a typical section of crop row. The cultivator

should be level and set onto the rows as accurately, and as straight as possible with the camera at

its normal operating height

(displayed in the “set up” screen).

Press button labelled

“Manual”, The overlaid green lines representing the template should lock in

the centre of the screen.

Green lines superimposed over the live image should align with crop rows as illustrated below.

Tip

If crop rows are difficult to see in the live video image you can enhance them by placing high

visibility objects such as a strip of wood exactly over the row centre line.

Caution

If the overlaid green lines are not symmetrical on the screen (by more than 4 degrees) the camera

skew value may need resetting. Refer to the advanced set up & diagnostics menu in section 7.3.

✓