8

1

2

3

4

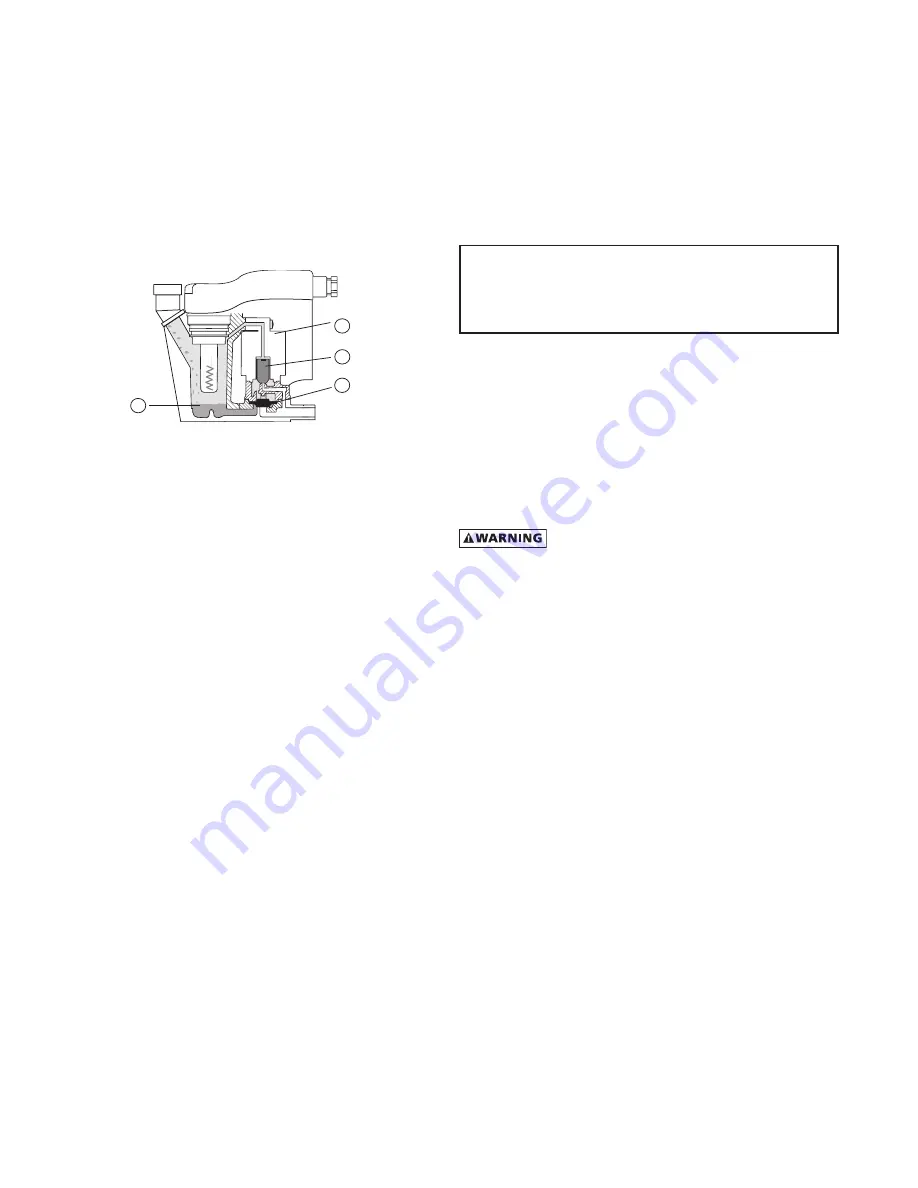

E. Condensate enters the reservoir

(1)

through the inlet

port. When the condensate level in the reservoir covers

the capacitance sensor, an electronic signal is sent to the

solid state countdown processor. The processor delays

the opening of the solenoid valve for a given period

of time. Once the time has elapsed, the solid state

processor transmits information to energize the coil in

the solenoid valve

(2)

. The magnetic force of the coil

causes the solenoid core

(3)

to move, closing the pilot air

supply line and opening the pilot air exhaust line. After

the pilot air above the diaphragm

(4)

is vented, pressure

in the reservoir opens the discharge port and forces

the condensate through the discharge port and outlet

piping.

2.8 Operating Instructions

– I-Controller Level 3

1. Check the following on a periodic basis:

a. Power-on light glows (green) indicating power to the

dryer

b. Compressor-on light glows (green) indicating the

refrigeration compressor is operating

c. VFTD is automatically scrolling every 3 seconds

through OPERATION mode readings and settings

d. Warning/Maintenance Alert light (yellow) is NOT

flashing

e. Alarm light (red) is NOT flashing

f. Condensate is draining

2. ALARM/ALERT Fault Condition Activation

(See wiring diagram for N/O contact location.)

Upon activation, text identifying the Fault will be

displayed on the VFTD. An Audible Alarm will sound, a

Flashing Panel light (Warning/Yellow or, Alarm/Red) and, a

Flashing Process Diagram LED (Green or Red) combine to

indicate the fault condition. Where applicable (see table

2 on page 20) a normally open (N/O) circuit will activate a

customer supplied remote alarm.

NOTE:

If yellow Alert light or, red Alarm light ARE flashing,

see fault condition identified in VFTD window. Reference the

condition in the Troubleshooting Guide on page 20.

3. REMOTE START/STOP Function

Software programming allows the dryer to be stopped

and started by a remotely controlled signal. Consult

factory for details.

4. DOWNLOADABLE MEMORY Function

Software programming allows the dryer to store the last

10 alarm related events. Output command delivers the

events complete with the date, time and, fault condition.

Consult factory for details.

5. RS-232 & RS-485 Communications Capable

Dedicated pin arrangement is used to monitor dryer

operation from a host computer. Consult factory for

details.

3.0 MAINTENANCE

3.1 Condenser coil

A. Air-cooled - clean off accumulated dust and dirt monthly

or as necessary in dirty environments.

B. Water-cooled - clean strainer monthly, more often if

required. Shut off water, remove small plug to relieve

pressure, then remove large plug to remove strainer.

Clean strainer and replace.

3.2 Moisture Separator/Oil Removal Filter

NOTE:

Prepackaged maintenance kits are available

that include all necessary filter and timed drain valve

components. Maintain maximum performance and

efficiency with Genuine Parts. See page 21 for ordering

information.

When to replace the Separator/Filters

Replace filter element when pressure drop across dryer is

excessive or annually.

Dryers have the option of one or two stages of filtration.

The directions for servicing either filter is identical.

When removing liquids at rated flow conditions, an

increase in pressure drop will occur as the separator/

filter elements become loaded with solid particles.

Procedure for Separator / Filter Element Replacement

THIS FILTER IS A PRESSURE CONTAINING DEVICE.

DEPRESSURIZE BEFORE SERVICING. If filter has not been

depressurized before disassembly, an audible alarm will sound

when the bowl begins to be removed from the head. If this

occurs, stop disassembly, isolate and completely depressurize

filter before proceeding.

1. Isolate dryer (close inlet and outlet valves if installed) or

shut off air supply.

2. Depressurize filter by slowly opening manual drain by-

pass valve.

3. Remove bowl

a. For models RNC100 through RNC150 - bayonet

mount - push bowl up, turn bowl 1/8th turn to your

left, and pull bowl straight down

b. For models RNC200 through RNC750 - threaded

bowls - unscrew bowl from head using hand, strap

wrench or C spanner.

4. Clean filter bowl

5. Replace moisture separator element.

a. Replacing complete Grade B element.

1) Pull off old element and discard

2) Make certain o-rings on male of replacement

element adaptor are in place and push element

into filter head.

NOTE:

Do not handle Oil Removal Filter elements by outside

foam cover. Handle by bottom end cap only.

Summary of Contents for RNC Series

Page 22: ...22 NOTES...

Page 23: ...23 NOTES...